Basic Info.

Model NO.

PPGC-

Nonwoven

150-200G/M2

Delivery Time

15 Days

Carbon Black

>2%

Transport Package

PE Film or Woven Plastic Bag

Specification

20-40KN

Trademark

ECL

Origin

China

HS Code

2623

Production Capacity

5 000 000m2/Year

Product Description

Biaxial PP/Polypropylene Geogrid Composite with Nonwoven Geotextile

- Composite Base Reinforcement

Instruction:

Composite Geogrids are geocomposites especially designed for soil stabilisation and reinforcement applications. The Composite PP Geogrids with Nonwoven geotextile are manufactured by bonding a Biaxial PP Polypropylene Geogrid to a nonwoven polyester geotextile.

Applications:

- Base Reinforcement.

- Subgrade stabilization.

- Slope stabilization / Protection

- Asphalt Reinforcement

Features:

- High-strength, low creep

- Good separation against moisture and gases to road base.

- Better bonding strength with base layers.

- Easy installation and save labor cost.

- Improve loading capacity of road foundation and extend its service life.

-.Extra stabilization to slopes by avoiding of water loss and soil erosion.

Technical Specification:

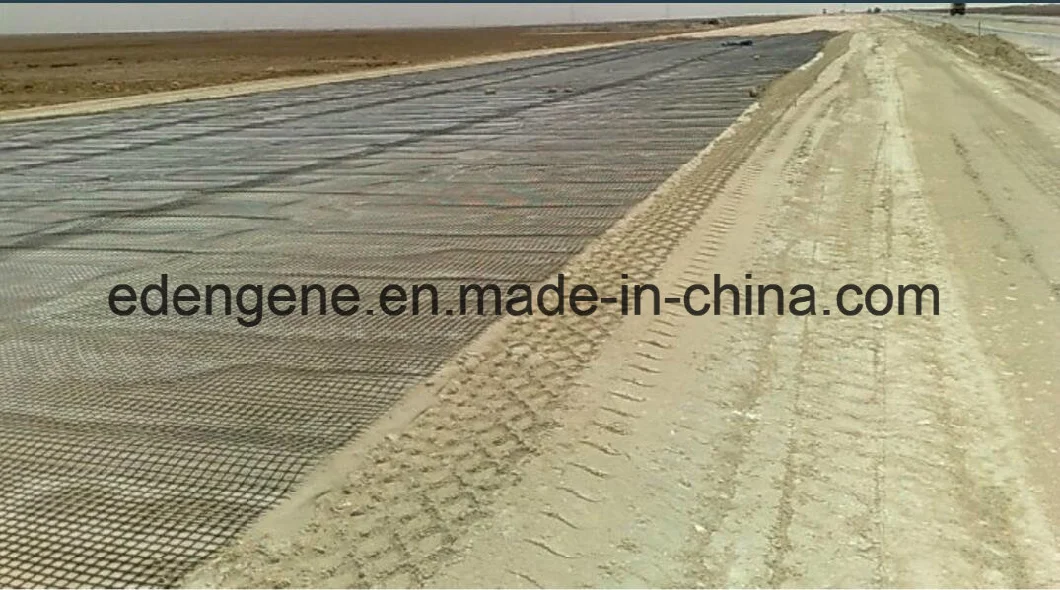

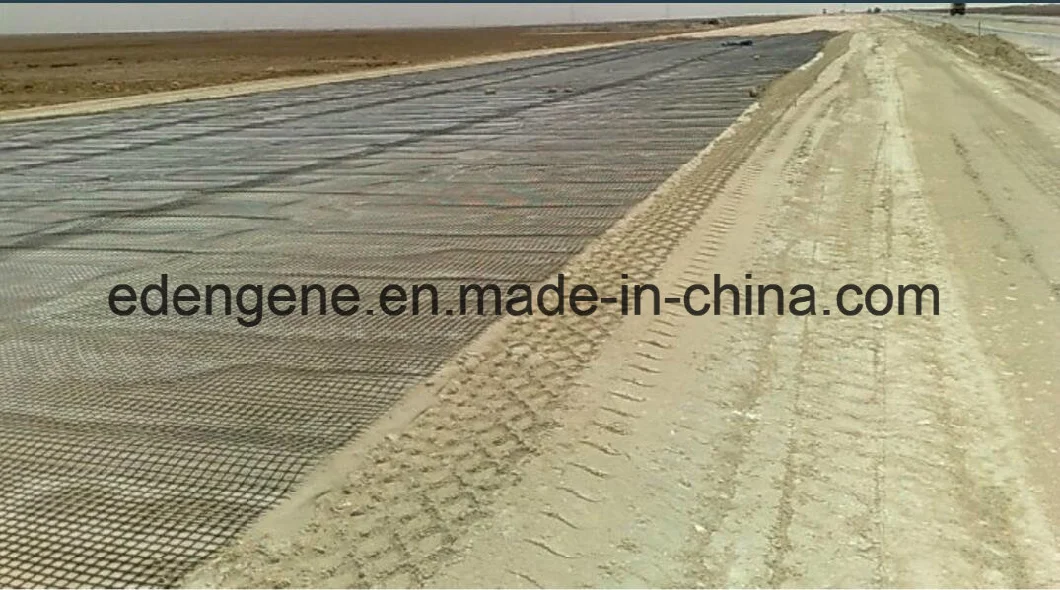

Projects Reference:

Production Processing:

- Composite Base Reinforcement

Instruction:

Composite Geogrids are geocomposites especially designed for soil stabilisation and reinforcement applications. The Composite PP Geogrids with Nonwoven geotextile are manufactured by bonding a Biaxial PP Polypropylene Geogrid to a nonwoven polyester geotextile.

Applications:

- Base Reinforcement.

- Subgrade stabilization.

- Slope stabilization / Protection

- Asphalt Reinforcement

Features:

- High-strength, low creep

- Good separation against moisture and gases to road base.

- Better bonding strength with base layers.

- Easy installation and save labor cost.

- Improve loading capacity of road foundation and extend its service life.

-.Extra stabilization to slopes by avoiding of water loss and soil erosion.

Technical Specification:

| Item Properties | Unit | PPGC-20C | PPGC-30C | PPGC-40C |

| Materials | / | PP Geogrid + Nonwoven | ||

| Nonwoven Geotextile | g/M2 | 150g, or customized | ||

| Minimum Carbon Black | % | 2 | ||

| Ultimate Tensile Strength MD x CMD | KN/M | 20 x 20 | 30 x 30 | 40 x 40 |

| Tensile Strength @ 2% Strain MD x CMD | KN/M | 7 x 7 | 10 x 10 | 14 x 14 |

| Tensile Strength @ 5% Strain MD x CMD | KN/M | 14 x 14 | 21 x 21 | 28 x 28 |

| Elongation at Ultimate | % | <13 | <13 | <13 |

| Roll Width | M | 3.9 Max. | ||

| Roll Length | M | 50 - 75 | ||

Projects Reference:

Production Processing: