- Overview

- Product Description

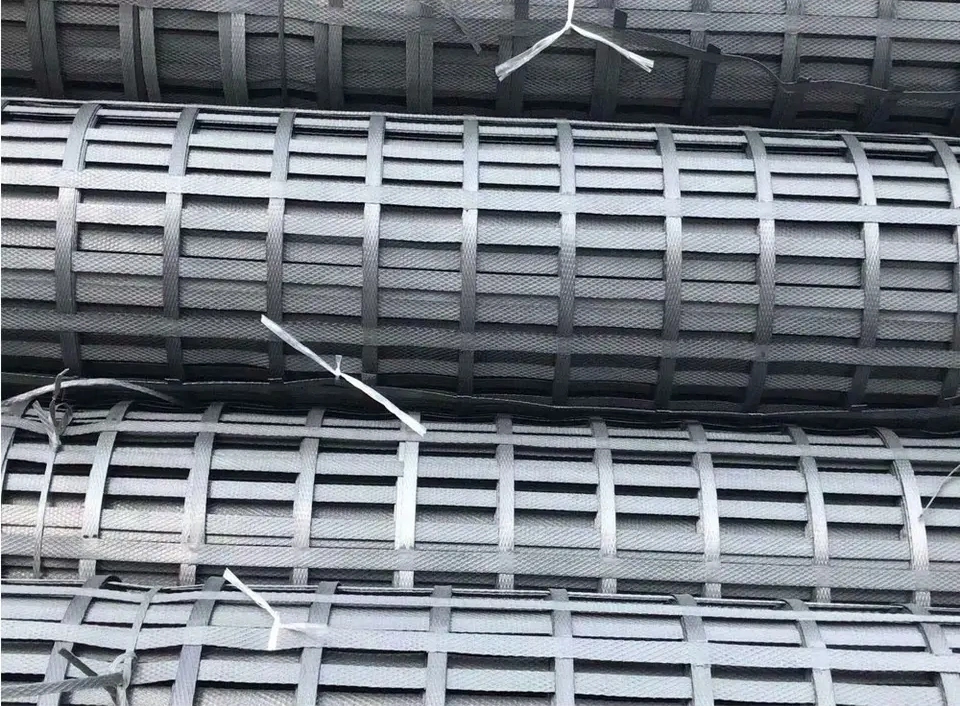

- Detailed Photos

- Product Features

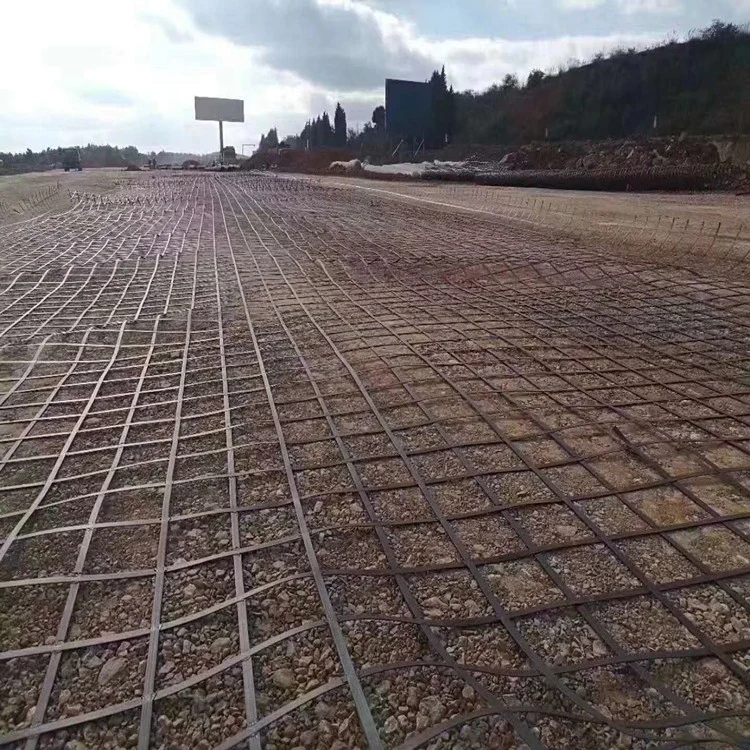

- Product Application

- Product Stock

- Certifications

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

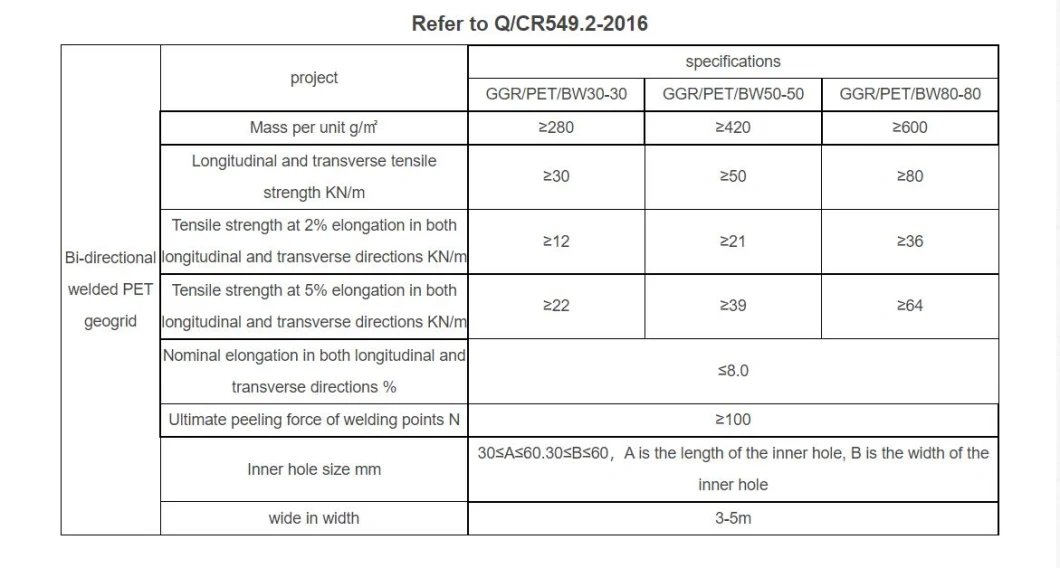

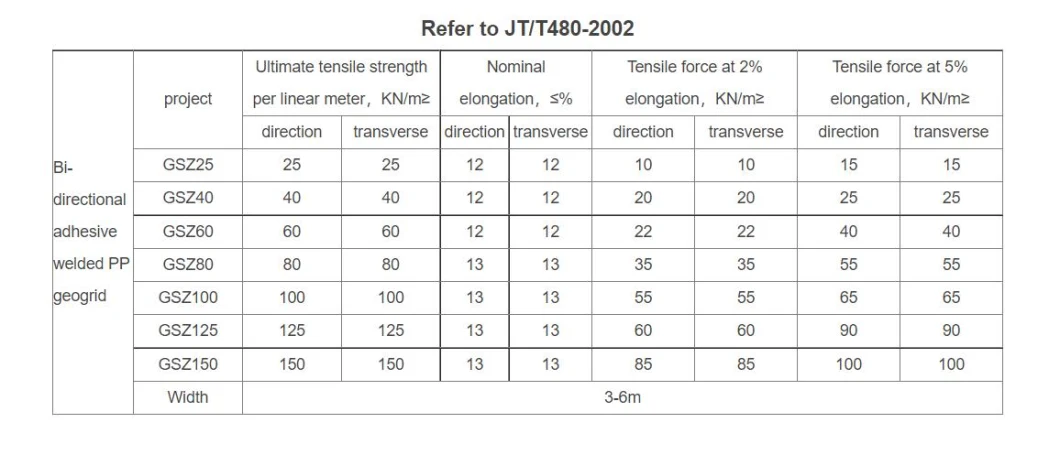

Technical index

| Steel plastic,special-shaped steel-plastic geogrid: JT/T 925.1-2014 | ||||||||

| Project | 30-30 | 50-50 | 60-60 | 70-70 | 80-80 | 100-100 | 120-120 | |

| Longitudinal and transverse ultimate tensile strength,KN/m≥ | 30 | 50 | 60 | 70 | 80 | 100 | 120 | |

| Elongation under longitudinal and transverse ultimate tensile strength,%≤ | 3 | |||||||

| Detached strength of junction,N≥ | 300 | 500 | ||||||

| Project | 50-30 | 60-30 | 80-30 | 80-50 | 100-50 | 120-50 | 180-50 | |

| Longitudinal ultimate tensile strength,KN/m≥ | 50 | 60 | 80 | 80 | 100 | 120 | 180 | |

| Transverse ultimate tensile strength,KN/m≥ | 30 | 30 | 30 | 50 | 50 | 50 | 50 | |

| Elongation under longitudinal and transverse ultimate tensile strength,%≤ | 3 | |||||||

| Detached strength of junction,N≥ | 300 | 500 | ||||||

Civil works such as roads, railways, embankments, abutments, construction roads, wharves, revetments, flood dikes, dams, mudflat treatment, freight yards, slag yards, airports, sports grounds, environmental protection buildings, soft soil foundation reinforcement, retaining wall reinforcement, high slope treatment, and exposed hydraulic works.

1,We have professional warehouse management system, not only keep clean and dry, but also ensure the packing. All the goods stock respectively according to different orders

2,Standard export packing, or customized packing as your request.

We have ISO9001 Quality Management System Authentication Certificate, ISO14001 Environmental Management System Authentication Certificate and ISO45001 Occupational Health and Safety Management System Authentication Certificate three qualifications, absolute quality assurance, Chuangwan trustworthy!

Anhui Chuangwan New Materials Co., Ltd. Is located in the industrial new town of Dashu town, Quanjiao county, Chuzhou city, which is the Jianghuai watershed where mountains and rivers are beautiful and humanities gather together in eastern Anhui, has been rising rapidly in the fierce market competition since its establishment in 2017 through the unremitting efforts of all Chuangwan people. It is a private science and technology enterprise specializing in the research, manufacturing and sales of high-speed railway (highway) polymer materials. The company has passed ISO9001-2015 Quality system certification, ISO14001-2015 Environmental management system certification, ISO45001-2018 Occupational Health and safety management system certification, China railway corporationrailway products - geosynthetic materials CRCC certification, now the product has diversified development.

Anhui Chuangwan New Materials Co., Ltd. Is located in the industrial new town of Dashu town, Quanjiao county, Chuzhou city, which is the Jianghuai watershed where mountains and rivers are beautiful and humanities gather together in eastern Anhui, has been rising rapidly in the fierce market competition since its establishment in 2017 through the unremitting efforts of all Chuangwan people. It is a private science and technology enterprise specializing in the research, manufacturing and sales of high-speed railway (highway) polymer materials. The company has passed ISO9001-2015 Quality system certification, ISO14001-2015 Environmental management system certification, ISO45001-2018 Occupational Health and safety management system certification, China railway corporationrailway products - geosynthetic materials CRCC certification, now the product has diversified development. We promise

1. Safety production

2. Ensure the quality of goods

3. Timely supply

4. Accept customization of any size specification

Q1. Can you do OEM?

A1. Yes.of course.We can produce the products as per your request.

If you can offer samples to us,it will be more convenient.

Q2. If I want to order a small quantity goods,can you do it?

A2. If the product you need we have stock available,that would be great,you can choose the instock goods. but if not, don't worry, we can take your order with our other clients' order to be produced together.But it needs to wait some time .

Q3. Can I get a sample from your company?Should I pay for the express fee?

A3. If you can accept our available sample,we can offer free sample to you.

If you want a customized sample,we can renegotiate the cost.

About the express fee,please offer a freight collected account and pay for the express fee by your side. After confirming your order, the sample's freight cost will be deducted from your order's total cost.

Q4. How will you follow my order?

A4. When the goods are started to produce,we will take photos for the goods and send it to you.

If you find any production deficiencies,please contact us to correct it.

We will keep in touch with you in the whole production by e-mail or instant messaging, like Skype/Viber/WhatsApp, you can get the latest news about your order.

After the goods are finish,we will take photos for the goods and packing to you before shipping.

Q5. What is your exporting countries?

A5. We have good sales performance and win good international reputation in more than 15 Countries and regions,such as Japan, America, Australia,Russia, Canada,Middle East and so on.