Basic Info.

Product Description

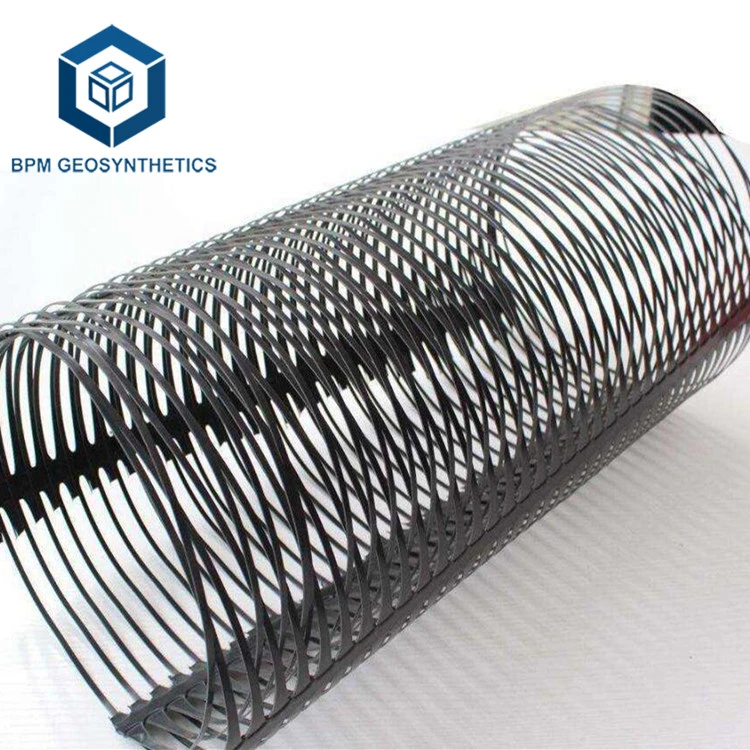

High Tensile Strength Polyester Uniaxial Biaxial HDPE Plastic Geogrid for Port Road Construction

High Tensile Strength Polyester Uniaxial Biaxial HDPE Plastic Geogrid for Port Road Construction is often made of high strength industrial polyester or polypropylene filament fiber as raw material and the warp knitting and directional structure composite weaving process. The meridional fiber yarn in the warp knitted Geogrid 120 has a strong bonding point, which has excellent mechanical properties and long-term strength stability. The Dacron geotechnical grille has the characteristics of high tensile strength, small extension force, strong strengthening ability, great strength of resistance to tear, balance of vertical and horizontal strength, abrasion resistance, corrosion resistance and light quality, which can effectively lock soil or gravel, greatly enhance the shear ability and overall stability of soil. Warp knitted Geogrid 120 is widely used in road, railway, municipal and other road soft soil foundation treatment and subgrade, embankment and other engineering reinforcement and protection.

Geogrid Specifications

| Item | TGSG15-15 | TGSG20-20 | TGSG25-25 | TGSG30-30 | TGSG35-35 | TGSG40-40 | |

|---|---|---|---|---|---|---|---|

| Tensile Strength (kN/m) | Longitudinal | ≥15 | ≥20 | ≥25 | ≥30 | ≥35 | ≥40 |

| Transverse | ≥15 | ≥20 | ≥25 | ≥30 | ≥35 | ≥40 | |

| Elongation Rate (%) | Longitudinal | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 |

| Transverse | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | |

| Strength at 2% elongation (KN/m) | Longitudinal | ≥5 | ≥8 | ≥8 | ≥11 | ≥12 | ≥13 |

| Transverse | ≥7 | ≥10 | ≥11 | ≥13 | ≥14 | ≥15 | |

| Strength at 5% elongation (≥KN/m) | Longitudinal | ≤8 | ≤10 | ≤11 | ≤15 | ≤15 | ≤16 |

| Transverse | ≤10 | ≤13 | ≤13 | ≤15 | ≤18 | ≤20 |

Applications

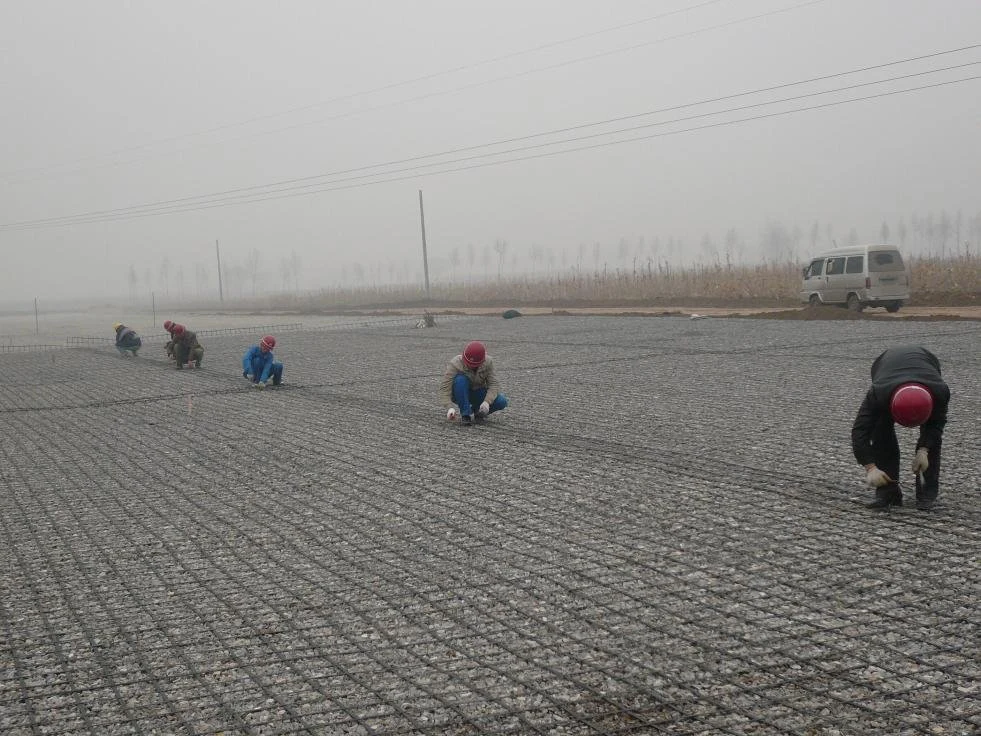

In the construction of port breakwater and cofferdam, the first problem to be solved is soft soil foundation. The soft soil foundation is usually treated by a combination of sand cushion and plastic drainage board, but due to the heavy load on the upper part, the uneven settlement and slip can be caused. Laying Geogrid 120 and filament non woven geogextile at the bottom will increase friction, reinforce subgrade and soft soil, greatly preventing uneven settlement and sliding movement, which plays an important role in increasing the overall stability of the port dam.

- High strength, small deformation.

- Good performance for seismic waves

- Excellent dimensional stability

- Strong bearing capacity

- High friction coefficient

- Low elongation rate at break

- Long service life

- Easy to install

Our Indonesia customer had a port construction project by bidding in December, 2017. The soft soil foundation is the important problem to be solved. Our engineer recommended Geogrid 120 and filament nonwoven geotextile product to increase the bearing capacity and stabilization of low load bearing soils. He visited our professional geosynthtics factory and Geogrid 120d automatic production lines, and take some samples back for third party lab testing. Two months later, he placed the order for 120,000 square meters filament non woven geotextile and 90,000 square meters HDPE biaxial Geogrid 120d. In the same time, the Indonesia customer paid for the deposit and confirmed delivery schedule, factory on-site inspection.

Specifications of Geogrid 120 for Slope Stabilization

- Total quantity - 90,000 m2

- Two 40HQ containers

Company Information

The Best Project Material Co., Ltd (BPM) is the leading geomembrane manufacturer and exporter since 2007. Our main innovative, highquality geomembranes include Smooth Geomembrane HDPE Liner, Textured HDPE Geomembrane, Composite Geomembrane Liner and other geosynthetic products .

BPM has provided many types of effective and states of the art geomembranes, geotextile and other geosynthetics to over 36 countries.

BPM is also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please send inquiry to us, we will reply as soon as possible.

BPM all products have been approved by the ISO9001,ISO14001 and BV certificates and passed the test of SGS,SONCAP,SASO etc.

Our Services1. Factory lab to test the fish farm dam liners quality.

2. Third party test is available.

3. Welding machine is available for one-stop purchase.

4. Welding team is also available for abroad installation.

5. Project suggestions & solutions are available based on our rich project experience.

6. Various product standard to meet your project needs.

7. Free samples are available.