- Overview

- Product Description

- Our Advantages

- Detailed Photos

- Packaging & Shipping

- Company Profile

- Certifications

Basic Info.

Product Description

The term is an extension of GI which is a traditional abbreviation for Galvanized Iron. Today the term GI typically refers to essentially pure zinc (>99%) continuously hot dip coated steel, as opposed to batch dip processes. PPGI refers to factory pre-painted zinc coated steel, where the steel is painted before forming, as opposed to post painting which occurs after forming.

| Location | category | value | |||||

| Executive standard | National standard | GB/T12754-2019 | |||||

| American Standard/European Standard | ASTM A792M | ||||||

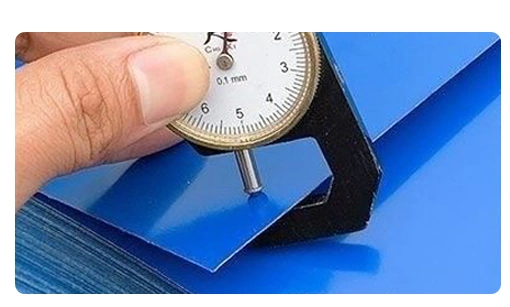

| Cold rolled substrate | Width specification | Cold rolled substrate thickness | Including metallized layer, the thickness after painting | Label thickness | |||

| 1200mm | ≥0.41mm | ≥0.46mm | ≥0.45mm | ||||

| Size deviation | Width tolerance | Upper deviation +4mm | |||||

| Lower deviation 0 | |||||||

| thickness | Upper deviation +0.05mm | ||||||

| Lower deviation 0 | |||||||

| Yield Strength | >300MPA | ||||||

| tensile strength | 270-500MPA | ||||||

| elongation after break | More than 20% | ||||||

| Steel coil inner diameter | Standard: 508mm,Except for other agreements | ||||||

| metal coating | alloy composition | AlZnMg or galvanized AlMg | |||||

| Total Weight of Plating Both Sides (Outside/Inside) | 150g/ (75/75 or 85/65) | ||||||

| Neutral salt spray test | The surface of the board (without passivation, anti-fingerprint and other treatments on the surface) has a neutral salt spray test of more than or equal to 2500 hours, and there is no red rust on the surface. | ||||||

| When the salt spray test on the wound surface (end surface) is greater than or equal to 1200, there is no red rust on the surface. | |||||||

| PPGI paint | PE coating structure standard (μm) | Paint structure | 2/1 | outside | ≥25 | ||

| Inside | ≥7 | ||||||

| pencil hardness | Not less than HB | ||||||

| Specular Gloss of Topcoat | Glossiness of finish paint mirror surface: ≥40 degrees | ||||||

| T bend value | 2T | ||||||

| Impact energy | Not less than 9J | ||||||

| Neutral salt spray test | Greater than or equal to 1500h without bubbles | ||||||

| UVB-313 | greater than or equal to 700h | ||||||

| PPGI use environment | humidity | 20% to 90% | |||||

| temperature | Min -45°C, Max 43°C | ||||||

| unit ammonia | <30ppm | ||||||

| unit carbon dioxide | <7000ppm | ||||||

| unit oxygen | 21% | ||||||

| unit hydrogen sulfide | <5ppm | ||||||

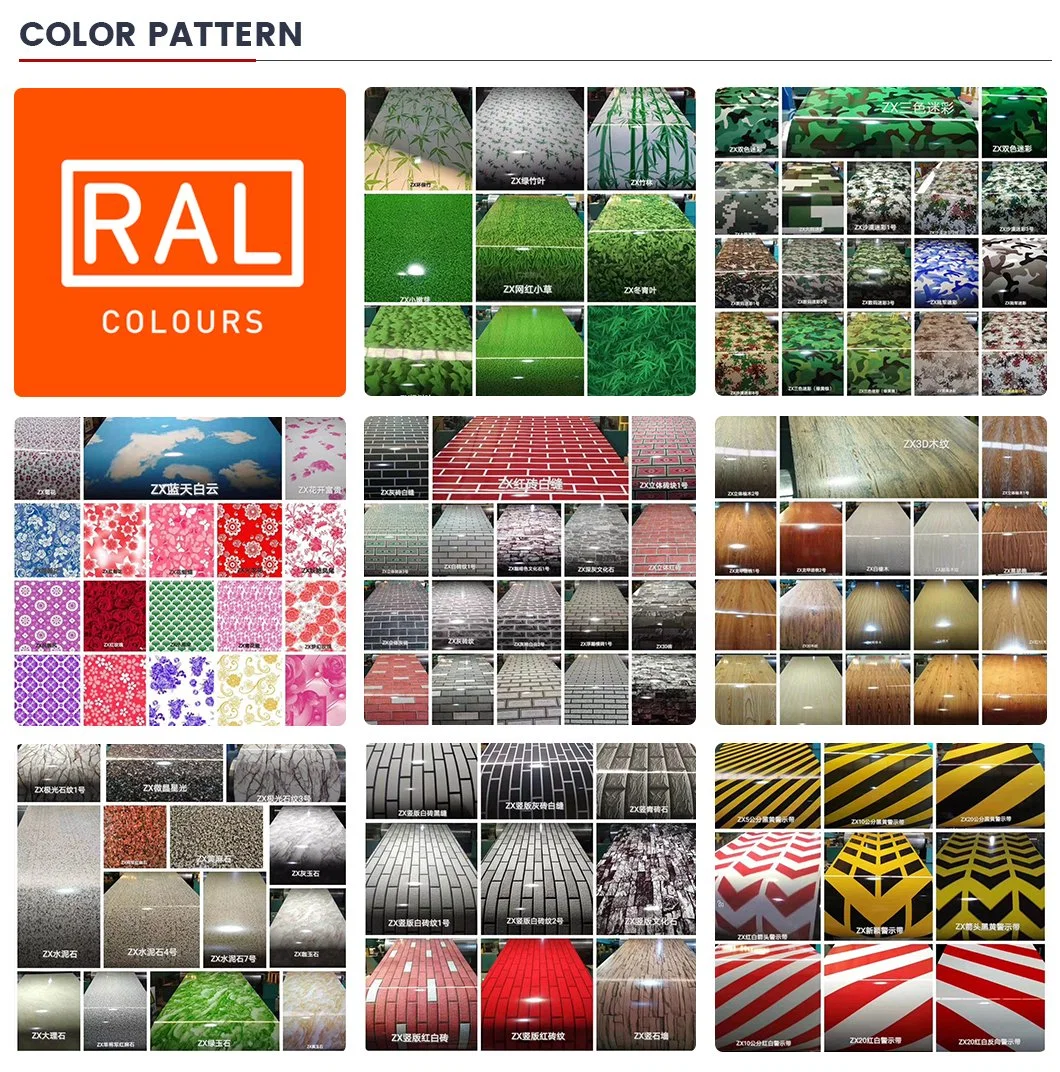

For the use of color steel coils, we have to choose different types of color steel coils to manufacture different PPGI. Speaking of this, I have to briefly introduce the types of color steel coils, which are divided into five categories. That is, home appliances, optical materials, decorative materials, building materials, and packaging. Among them, the production process of color steel coils for home appliances is the most delicate and perfect.

Zhengde color coated steel plate refers to the coating product obtained by applying organic paint to the surface of thin steel plate. PPGI has good anti-corrosion and decorative properties, as well as the good formability and processing properties of organic polymers and steel plates.

Before PPGI production, each post cleans the surrounding environment, ground sanitation, equipment spot inspection and each roller surface that directly affects the surface quality of the product in the working area according to the "Workshop 5S Management System" to ensure personal safety. At the same time, prepare tools, auxiliary materials, raw materials, etc. within the specified time. Ensure that the ground in the work area is free from dust, water and oil, ensure that the equipment is in the best condition and that the materials are used correctly.

PPGI image defects, surface defects, trace defects, edge defects, gold plating defects, size defects, coating defects, uneven defects, contamination defects, coating uneven defects, process defects, coating surface defects, physical property defects.

Quality first: production and inspection in strict accordance with production standards;

Price advantage: discounts based on real market prices;

Transaction security: There will be no loss of customer funds;

After-sales guarantee: the customer's problem is our problem;

Long-term cooperation: quality assurance, price advantage, sincere service can last for a long time.

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.