Basic Info.

Model NO.

KHCS

Door

Steel Door/Sandwich Panel Door

Connection

Screws, Bolts

Transport Package

Water Proof

Specification

ISO SGS

Trademark

K-HOME

Origin

Henan, China

HS Code

7308900000

Production Capacity

5000 PCS/Month

Product Description

Prefabricated Modular Hospital Construction

Because of the large number of patients and the limited number of beds in hospitals, how to accommodate more patients is bound to

become a thorny problem for hospitals and the government.

The thorny problem is reflected in several aspects, one is the problem of space, the other is the problem of time.

The space problem is "how to accommodate so many people in a certain space"; the time problem is "how to quickly and safely treat patients".

And our modular hospital, perhaps, is exactly what you need.

First of all, the construction cycle of Mobile Clinic Container is short.

Modular building is a new building structure system, which takes each room as a module unit, prefabricated in the factory,

transported to the site after completion, and assembled into a whole building through reliable connection.

It can be simply understood that according to the function and the number of units in advance,

the prefabricated boards and connectors can be used as children's building blocks and toys to combine the units into a building space.

Secondly, the stability of modular hospitals is high.

Each room and overall structure of the hospital is composed of steel frames and customizable functions,

such as various restaurants and toilets, doors and windows, as well as additional facilities such as porch and garage.

Although there are only some modular designs, housing helps to introduce the concept of modularity to the public.

This not only allows more patients to be treated in a short time but also improves the reputation of the hospital.

Finally, the cost of modular hospitals is low.

When the natural disaster comes, it is too late to build the traditional reinforced concrete hospital, and the traditional construction

method is not only high cost, long cycle but also not high practicability.

The Modular Container Clinic recommended by our company is not only short in the construction period but also convenient in transportation

and movement. It can follow you to the place you need.

Because of its convenient disassembly and assembly, it is very popular with the government departments of public facilities.

When you don't know when the disaster and epidemic will come, every department should do a good job in the reserve of

emergency facilities. As the sales of our company's products are quite hot, I suggest you customize them in advance.

We have professional designers. If you don't know enough about the website, you can visit our factory.

We are located in Xinxiang City, Henan Province, China. 24-hour service for you.

Looking forward to your call and asking price.

Detail Specification:

Because of the large number of patients and the limited number of beds in hospitals, how to accommodate more patients is bound to

become a thorny problem for hospitals and the government.

The thorny problem is reflected in several aspects, one is the problem of space, the other is the problem of time.

The space problem is "how to accommodate so many people in a certain space"; the time problem is "how to quickly and safely treat patients".

And our modular hospital, perhaps, is exactly what you need.

First of all, the construction cycle of Mobile Clinic Container is short.

Modular building is a new building structure system, which takes each room as a module unit, prefabricated in the factory,

transported to the site after completion, and assembled into a whole building through reliable connection.

It can be simply understood that according to the function and the number of units in advance,

the prefabricated boards and connectors can be used as children's building blocks and toys to combine the units into a building space.

Secondly, the stability of modular hospitals is high.

Each room and overall structure of the hospital is composed of steel frames and customizable functions,

such as various restaurants and toilets, doors and windows, as well as additional facilities such as porch and garage.

Although there are only some modular designs, housing helps to introduce the concept of modularity to the public.

This not only allows more patients to be treated in a short time but also improves the reputation of the hospital.

Finally, the cost of modular hospitals is low.

When the natural disaster comes, it is too late to build the traditional reinforced concrete hospital, and the traditional construction

method is not only high cost, long cycle but also not high practicability.

The Modular Container Clinic recommended by our company is not only short in the construction period but also convenient in transportation

and movement. It can follow you to the place you need.

Because of its convenient disassembly and assembly, it is very popular with the government departments of public facilities.

When you don't know when the disaster and epidemic will come, every department should do a good job in the reserve of

emergency facilities. As the sales of our company's products are quite hot, I suggest you customize them in advance.

We have professional designers. If you don't know enough about the website, you can visit our factory.

We are located in Xinxiang City, Henan Province, China. 24-hour service for you.

Looking forward to your call and asking price.

Detail Specification:

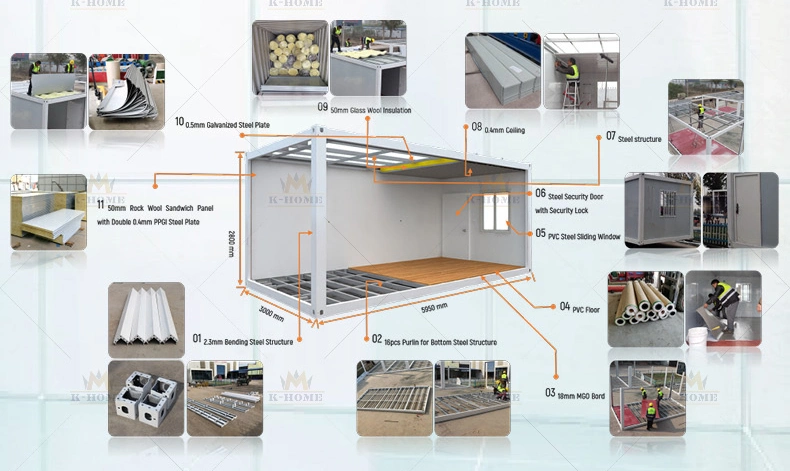

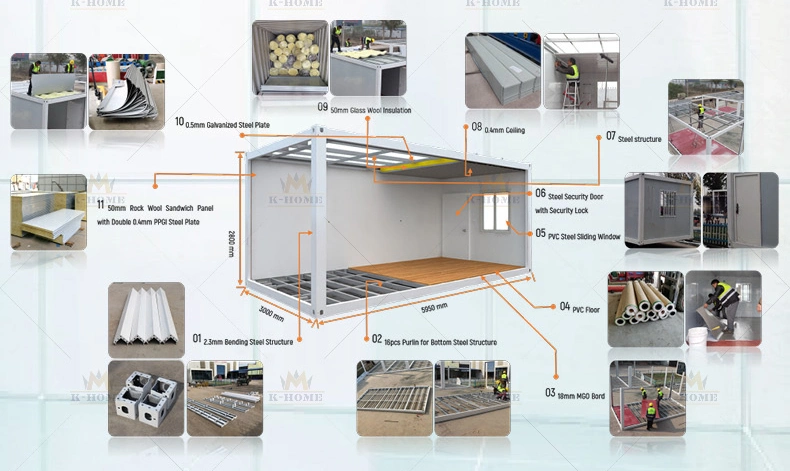

| Container House Size: 2400*5950*2800mm | ||

| Detail Parts | ||

| Part 1 | Roof System (roof plate + roof purlin + roof insulation + ceiling) | |

| 1 | Roof Plate | Roof tile is 0.5 mm thickness steel sheet; Pre-coated and color coated; |

| 2 | Roof Purlin | 1pc 40x80mm Galvanized Square tube + 2pcs 40x60mm Galvanized Square tube + 5pcs 40x80mm Galvanized Square tube; |

| 3 | Roof Insulation | 50 mm glass wool insulation material; |

4 | Ceiling | Ceiling is 0.4 mm thickness shaped steel plate; Pre-coated and color coated; |

| Part 2 | Steel Frame (Corner post + column + beam + bolt) | |

| 1 | Corner Connection Part | Material: 4 mm Thickness Shaped Steel, surface spray treated by machine after repeatedly polished; Size: 160* 160* 160 mm (Bottom) &160* 160* 180 mm (Top); |

| 2 | Column | Material: 2.3mm Thickness galvanized steel structure, surface spray treated by machine after repeatedly polished; Size: 160* 160* 2480mm; |

| 3 | Top and Floor Long Beam | Material: 2.3mm Thickness galvanized steel structure, surface spray treated by machine after repeatedly polished; Size: 5730* 60* 160 mm; |

| 4 | Top & Floor Short Beam | Material: 2.3mm Thickness galvanized steel structure, surface spray treated by machine after repeatedly polished; Size: 2780* 60* 160 mm; |

| 5 | Bolt | High strength galvanized steel bolt; To fix the Corner Connection Part and beam, Corner Connection Part and column; |

| Part 3 | Floor System (Floor structure + floor panel + floor leather) | |

| 1 | Floor Purlin | Material: 10pcs 40x60mm Galvanized Square tube +4pcs 40x80mm Galvanized Square tube +2pcs 30x50mm Galvanized Square tube; |

| 2 | Floor Panel | 18 mm MGO board; |

| Part 4 | Wall Panel | |

| 1 | Standard Wall Panel | 50 mm rock wool sandwich Panel; Outside color is light silver gray (0.38mm thickness ordinary steel ); Inside is white color steel (0.38mm thickness ordinary steel ). |

| Part 5 | Drainage system (Top drainage channel + drain pipe) | |

| 1 | Water drain pipe and channel | Water drain pipe: Diameter: 50mm Length: 2700mm; Water drain channel: 90(W)x50(H)mm; |

| Part 6 | Door & window system | |

| 1 | Door | Entrance door: 0.5mm thickness steel door; The interior is filled with composite wood to make the door heavy and strong; Width 930mm, height 2000mm. |

| 2 | Window | Plastic steel sliding window (including screens); With 0.35mm Double glass and strength pvc window frame; Width 930mm, height 1200mm; Window rail is smooth. |

| Part 7 | Connection Accessories | |

| 1 | Sealing Strip | Used on the joint between wall panel and steel frame for better waterproof performance. |

| 2 | Lock | Used when two containers connected with each other. As you tighten the lock, the containers will be fixed together strongly. |

| 3 | Joints Cover | Material: Rubber When there are two containers connected with each other, it is used in the joint between two containers for better fixation. |

| 4 | Waterproof Tape | Type: Self-adhesive Features: Waterproof; reliably sealing; strong adhesive strength; anti-corrosive |

| Part 8 | Electricity System | |

| 1 | Lamp | |

| 2 | Socket & Switch | |

| 3 | Electric Wire | |

| 4 | Air Circuit Breaker | |

| Part 9 | Internal Decoration | |

| 1 | Internal Corner | Material: PVC; Includes: Vertical internal corner and horizontal internal corner. |

| 2 | Steel Plate for Internal Connection | Material: Stainless Steel; Used on the joints between two bottom frames when different containers connected with each other. |

| 3 | Floor Leather | Material: PVC Thickness: 1.6mm Features: moisture proof; wear resisting; anti-corrosive and thermal insulation. 1.6 mm PVC Floor Leather Feathers: Excellent appearance, affordable, easy to clean and green environmental protection; |

| Part 10 | Accessories | |

| 1 | Sealant | Used for the joints of doors and windows for better waterproof. |

| 2 | Structure Adhesive | Used for the reinforcement and seal of the steel frames. |

| 3 | Screws | Include: rivets, bolts, drill tail screw; |