Basic Info.

Model NO.

wantong

Type

Geocells

Product Name

Direct Factory Supply ASTM Standard HDPE Geocell

Thickness

1.1mm-1.6mm

Surface

Textured Smooth

Height

50mm~200mm

Description

Plastic Parking Grass Grid Geocell

Welding Distance

330mm-1000mm

Certifications

SGS

Package

Plastic Packing Belts

Corrosion Resistance

Excellent Corrosion Resistance

Certificate

Ce/ISO9001/ISO14001

Place of Origin

Shandong, China

Supply Ability

50000 Square Meter/Square Meters Per Month

Packaging Details

Pallet or Supplied Package with Your Requirement

Weld Spacing

330-356-400-445-500-660-712mm

Transport Package

Pallet Packaging

Specification

100-350/1.1

Trademark

wantong

Origin

Shandong

HS Code

3926909090

Production Capacity

50000square Meters Per Month

Product Description

Tested in multiple directions Strengthening expert geocell for road slope

(1)Product Description:

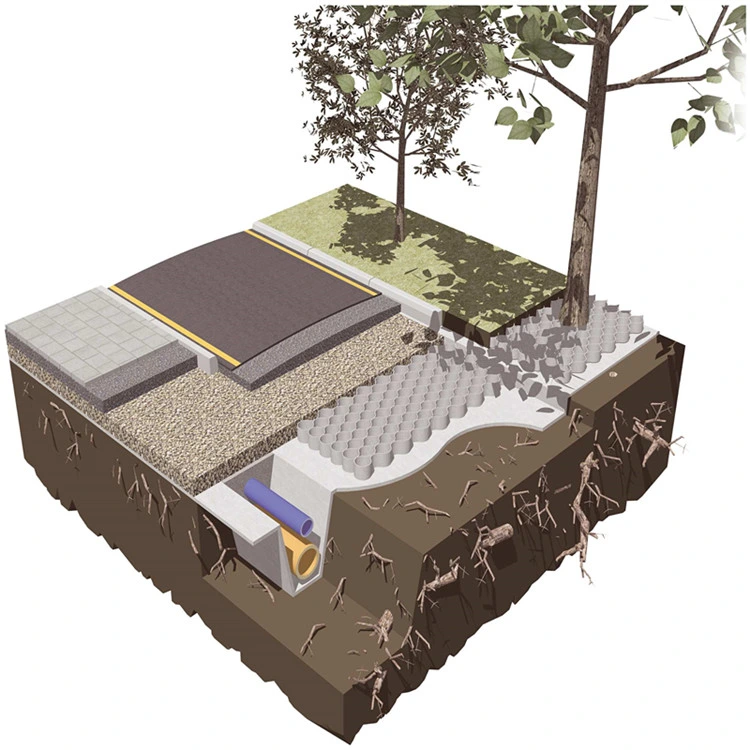

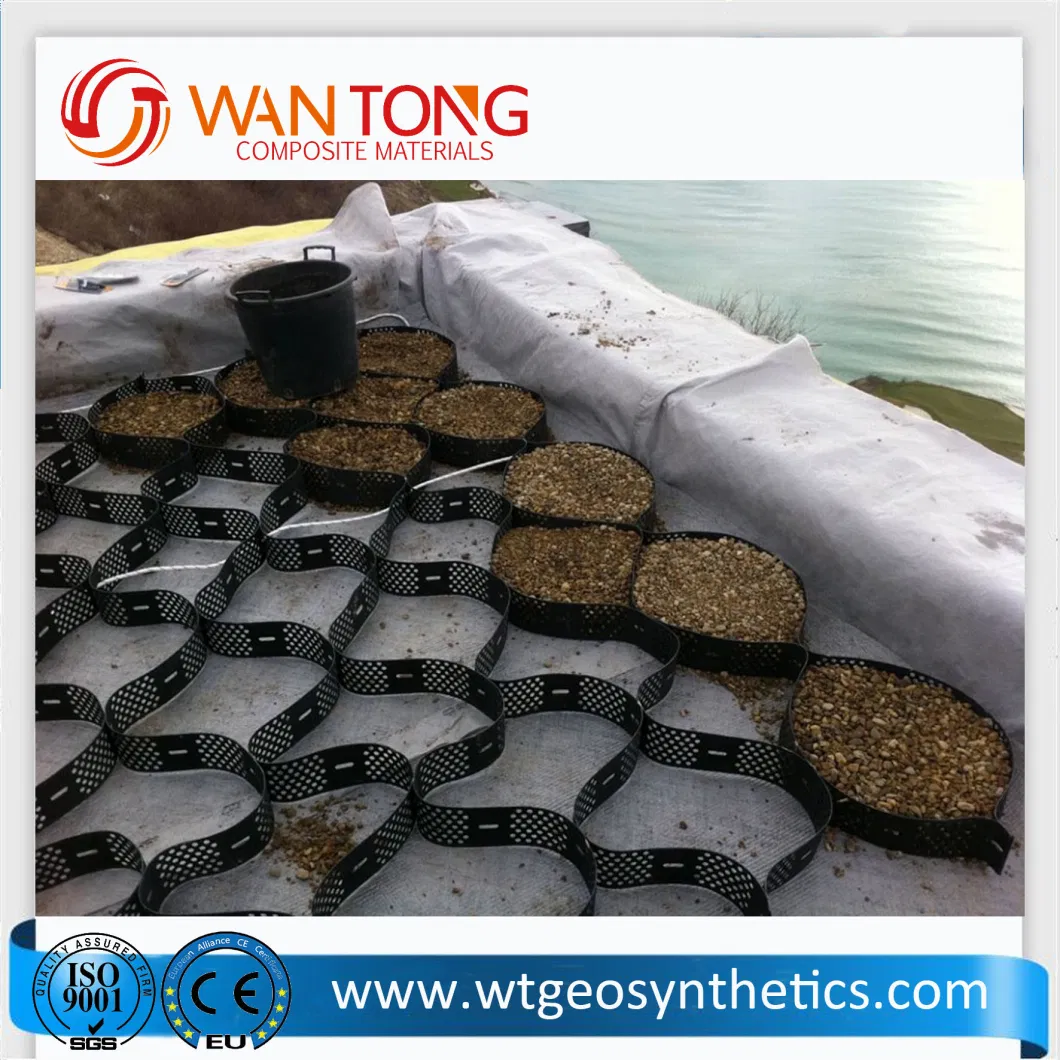

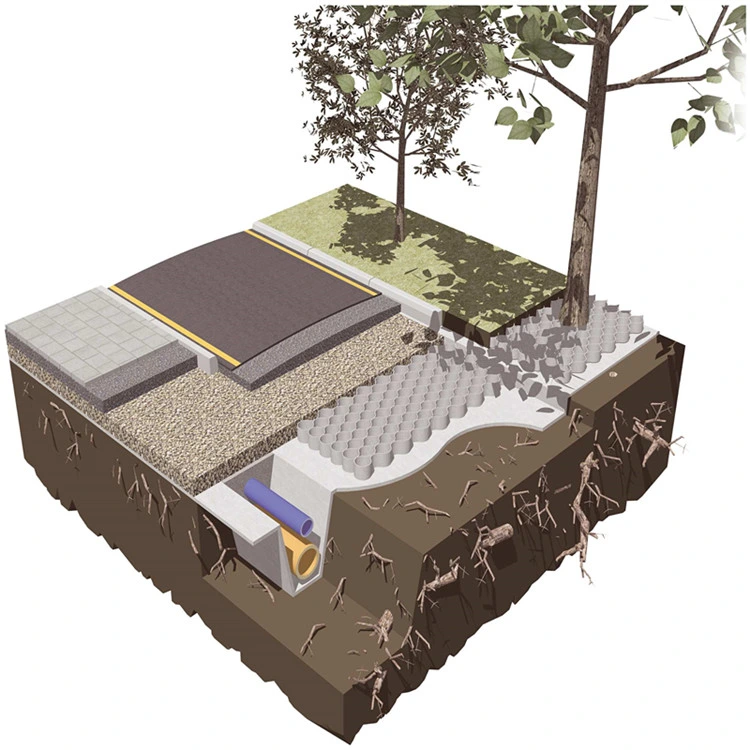

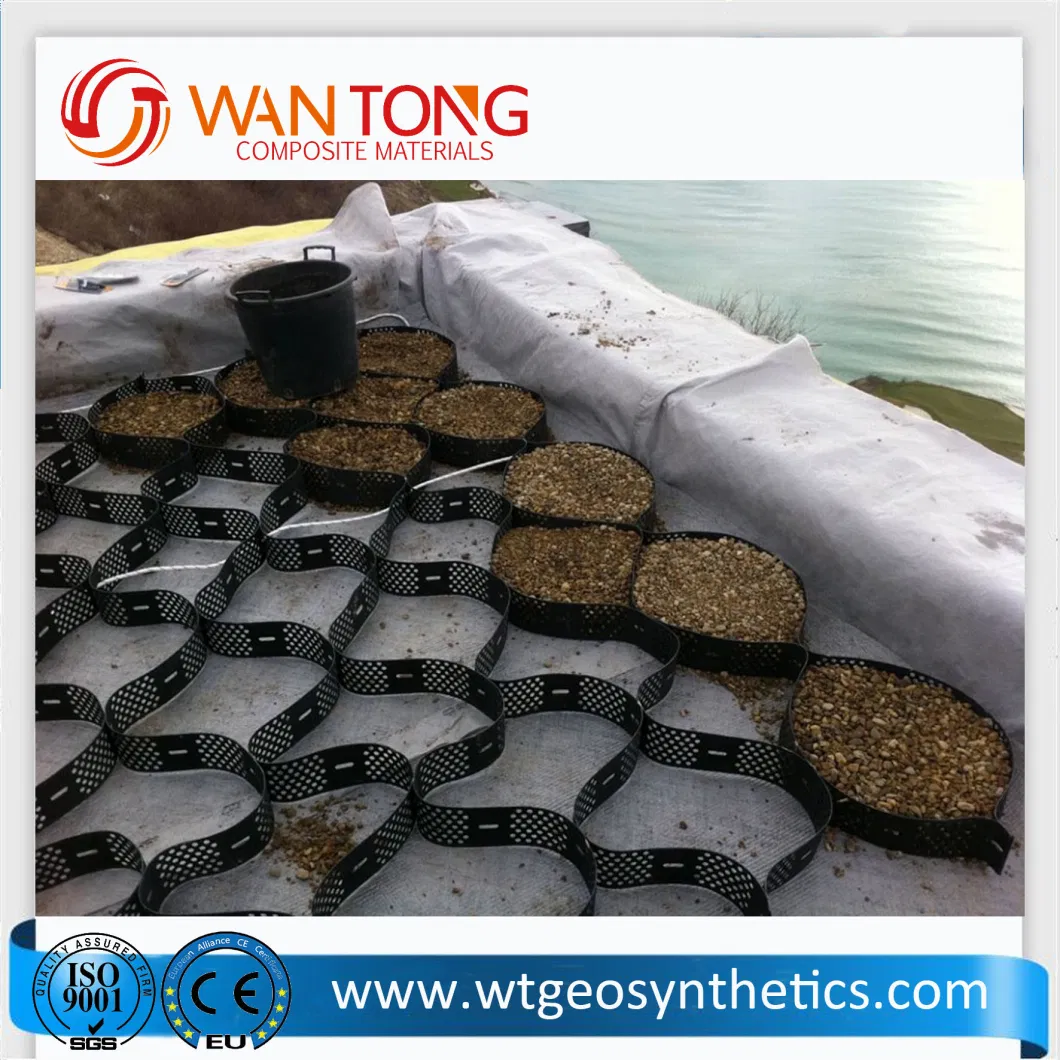

The geocell is a kind of 3d mesh cell structure formed by high strength welding of reinforced HDPE sheet material.

Generally by ultrasonic needle welding.Due to engineering needs, some holes in the diaphragm.

The geocell is a mesh cell structure formed by high strength HDPE or PP copolymer broadband, after strong welding or riveting

It retractable, transport can be folded up, when the use of the expansion and filling of soil and stone or concrete, with a strong lateral constraints and stiffness of the structure

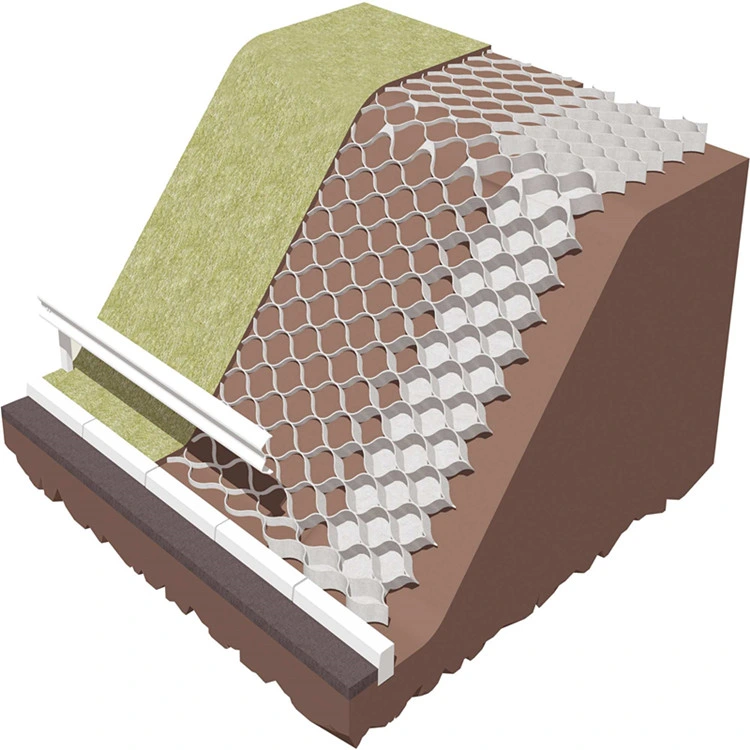

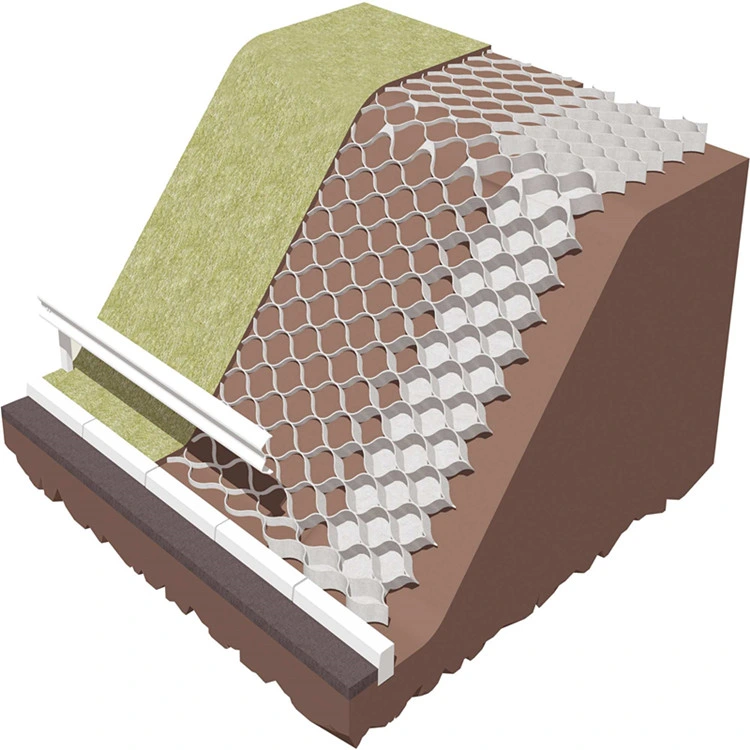

It can be used as a cushion to increase the bearing capacity of soft foundation, or laid on the slope to form a slope protection structure, but also can be used to build retaining structure.

(2)Product Function:

(3)product performance

Our company cooperates with many companies, Our product test results are fully up to international standards

The table is our test result

We are very strict with materials, We do a lot of testing on raw materials

(4)our Certifications

we have obtained ISO9001 certificate SGS certificate and CE certificate. Our products are widely applied in many fields, such as road, highway, airway, coal mine, water and soil conservation, water conservancy and basic construction.

(5) Our Workshop

In recent years, our company has introduced a series of advanced equipment including 40 production lines for various kinds of geosynthetics products.Such as 28 geogrid production lines,2 geotextile production lines, 2 geomembrane production lines,1 geocell producttion lines, 2 nonwoven fabric roll production lines and 10 other new composite material production lines.

(7)contact us

(1)Product Description:

The geocell is a kind of 3d mesh cell structure formed by high strength welding of reinforced HDPE sheet material.

Generally by ultrasonic needle welding.Due to engineering needs, some holes in the diaphragm.

The geocell is a mesh cell structure formed by high strength HDPE or PP copolymer broadband, after strong welding or riveting

It retractable, transport can be folded up, when the use of the expansion and filling of soil and stone or concrete, with a strong lateral constraints and stiffness of the structure

It can be used as a cushion to increase the bearing capacity of soft foundation, or laid on the slope to form a slope protection structure, but also can be used to build retaining structure.

(2)Product Function:

1.To stable the roadbed of railway.

2.To stable the roadbed of highroad.

3.To bear the load of dike or retaining wall.

4.To the improvement of shallow riverway.

5.To support the pipeline and sewer.

6.For the prevention of landslide by useing geocell as a heavy-duty hybrid force retaining wall.

7.To be used as independent wall, wharf and breakwater, etc.

8.For the desert, beaches and the riverbed, the river bank`s regulation.

(3)product performance

Our company cooperates with many companies, Our product test results are fully up to international standards

The table is our test result

We are very strict with materials, We do a lot of testing on raw materials

| Material Properties | Unit | Test Method | ||||

| Cell Depth | mm | 75 | 100 | 150 | 200 | |

| Polymer Density | g/cm3 | 0.935-0.965 | ASTM D1505 | |||

| Enviromental Stress Crack Resistance | Hours | >400 | ASTM D5397 | |||

| Enviromental Stress Crack Resistance | Hours | 6000 | ASTM D1693 | |||

| Carbon Black Content | % | 1.5%-2.0% | ASTM D1603 | |||

| Nominal Sheet Thickness Before Texturing | mm | 1.27-5%+10% | ASTM D5199 | |||

| Nominal Sheet Thickness After Texturingg | mm | 1.52-5%+10% | ASTM D5199 | |||

| Strip Puncture Resistance | N | 450 | ASTM D4833 | |||

| Seam Peel Strength | N | 1065 | 1420 | 2130 | 2840 | EN ISO13426-18 |

| Seam Efficiency | % | 100 | GRI-GS13 | |||

| Nominal Expanded Cell Size(width×length) | mm | 320×287.475×508 etc | ||||

| Nominal Expanded Panel Size(width×length) | m | 2.56×8.35 4.5×5.0 6.5×4.5 6.1×2.44 | ||||

(4)our Certifications

we have obtained ISO9001 certificate SGS certificate and CE certificate. Our products are widely applied in many fields, such as road, highway, airway, coal mine, water and soil conservation, water conservancy and basic construction.

(5) Our Workshop

In recent years, our company has introduced a series of advanced equipment including 40 production lines for various kinds of geosynthetics products.Such as 28 geogrid production lines,2 geotextile production lines, 2 geomembrane production lines,1 geocell producttion lines, 2 nonwoven fabric roll production lines and 10 other new composite material production lines.

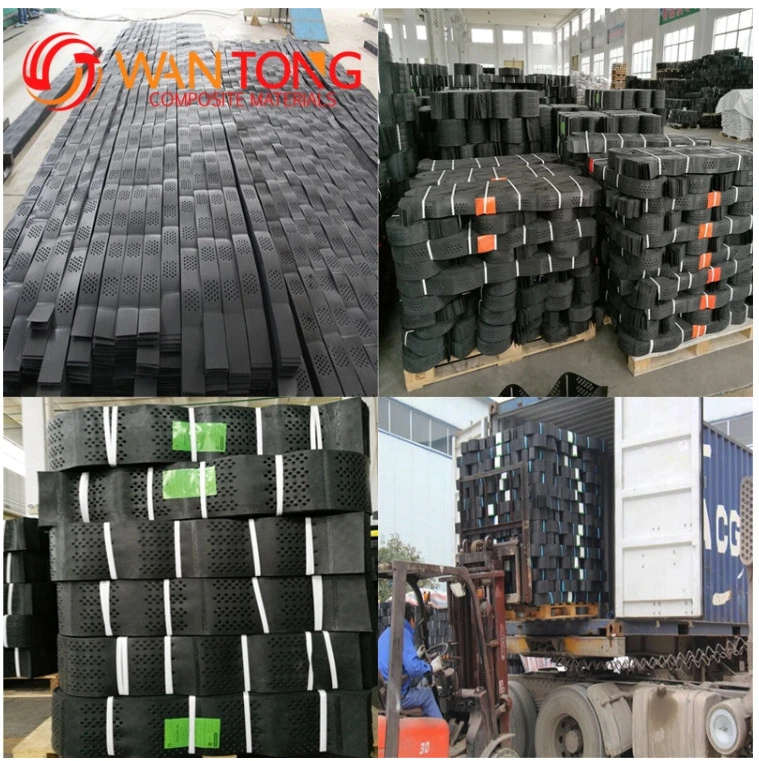

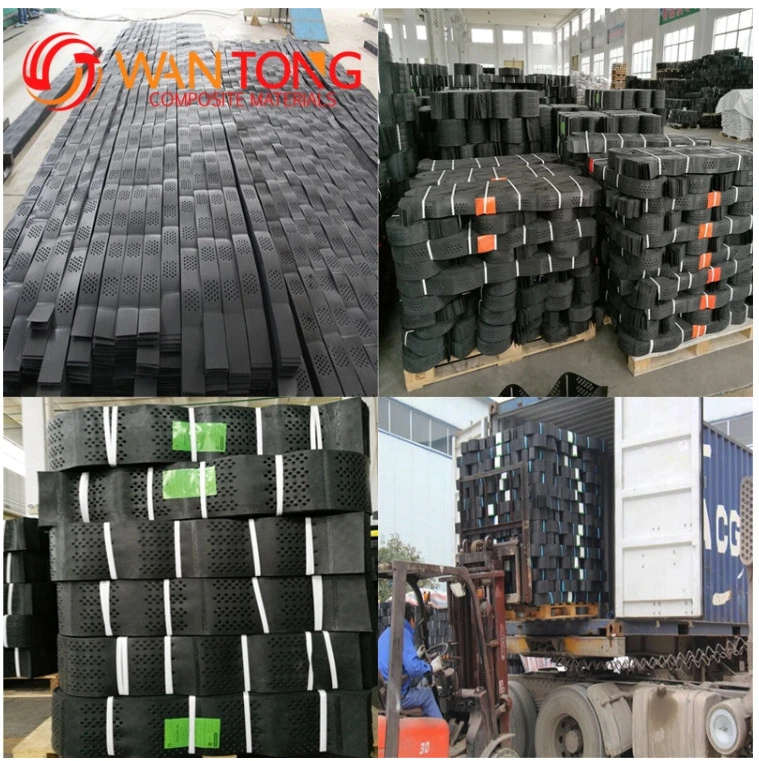

(6) Packaging & Shipping

We focus on every aspect of packaging, We seek to ensure the safety of our goods in transit, We can avoid any trouble in transit

(7)contact us