- Overview

- Product Description

- After Sales Service

- Certifications

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

| Product name | color coated steel coil ppgi | |||

| Thickness | 0.12-2.0mm | |||

| Width | 600-1500mm, usually 1250mm,1000mm,1240mm,1500mm,914mm,750mm and so on. | |||

| Grade | DX51D,Q235,SGCC,G550,S550 | |||

| Application | Inner decoration/School board/Making boxing | |||

| Paint Top (microns) | 15-35 microns | |||

| Paint Back (microns) | 5-10 microns | |||

| Coil ID | 508/610 mm | |||

| Coating | AZ30-AZ160, Z50-Z140g/m2 | |||

| Surface | Matt, high gloss, double coated, wood pattern, marble pattern, winkle | |||

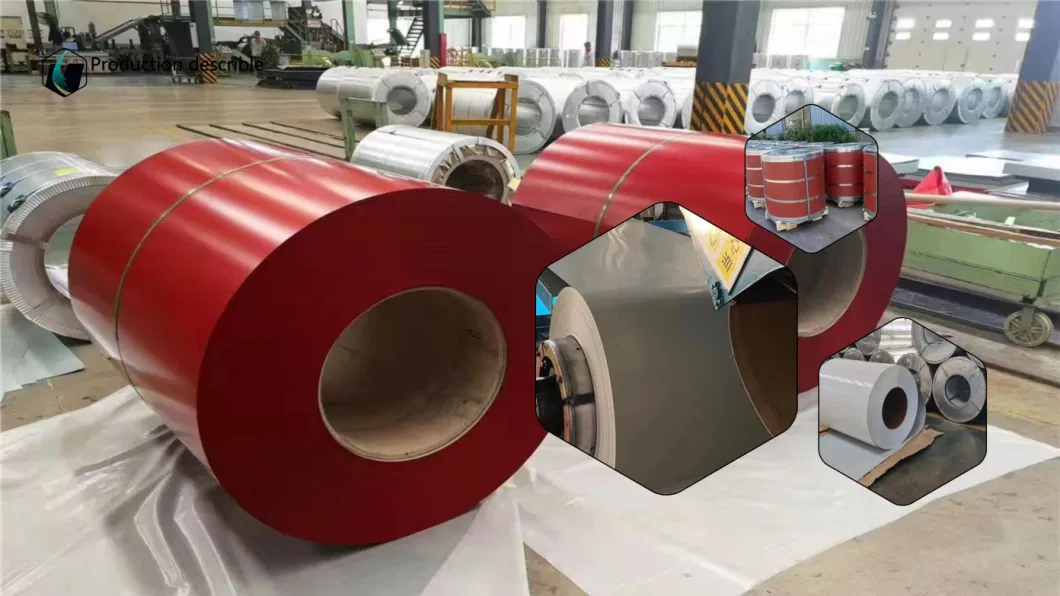

Color-coated coils are based on hot-dip galvanized sheets, hot-dip galvalume sheets, electro-galvanized sheets, etc. After surface pretreatment (chemical degreasing and chemical conversion treatment), one or more layers of organic paint are applied to the surface, and then After baking and curing products. It is named after the colored steel coil coated with various organic coatings of different colors, referred to as color coated coil.

Coating type of pre-painted coil

Polyester (PE)

Good adhesion, rich colors, wide range in formability and outdoor durability, moderate chemical resistance, and low cost.

Silicon modified polyester

That is (SMP), the hardness of the coating film, abrasion resistance and heat resistance are good, as well as good external durability and chalking resistance, gloss retention, flexibility, and medium cost.

High durability polyester

Namely (HDP), excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good paint film adhesion, rich colors, and excellent cost performance.

Polyvinylidene fluoride

Namely (PVDF), excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good moldability, dirt resistance, limited color and high cost.

1. Stable Quality:

we use our excellent equipment and technology and vast experience to manufacture products with stable quality under strict control throughout all process including pig iron manufacturing, steel manufacturing, heating, rolling and cooling.

2. Flawless Surface:

Using material (slabs) manufactured under a strict quality control system, we manufacture steel plates with flawless surface by removing scales from the steel plates with high pressure water jets during the rolling process. In addition, in the transport and heat treatment, etc. of steel plates, manufacturing is conducted using state-of-the-art equipment.

3. Wide availability:

We provide a wide product availability including steel plates that satisfy official standards in Japan and overseas, high tensile strength steel for welded structures, abrasion resistant steel, atmospheric corrosion resistant steel, low-temperature service steel, and steel for building, as well as materials that are suitable for a wide variety of uses,from offshore structures (production), line pipes (transport) tanks (storage) and other high-function steel for use in energy fields. In addition, we also accept orders for steel with special specifications, such as extra-thick steel plates for molds, electromagnetic soft iron, and chromium molybdenum steel for use in high temperatures. we also provide shot blasting and primer coating upon request. We also manufacture extra-heavy thick steel plates for use in nuclear power plants, thermal power plants, hydraulic power plants, petrochemical plants and the like.

4. On-time Delivery:

We strive for on-time delivery by making the most of the advantageous seaside location of each steel mill and our control systems for each individual product under process control that effectively utilizes a computer system.

5. Precise Consulting:

The engineering divisions at our head office and various branch offices canprecisely provide consulting on the quality characteristics, applications, and processing methods of steel plates as well as technical cooperation during use, based on their vast experience and comprehensive technical capabilities.

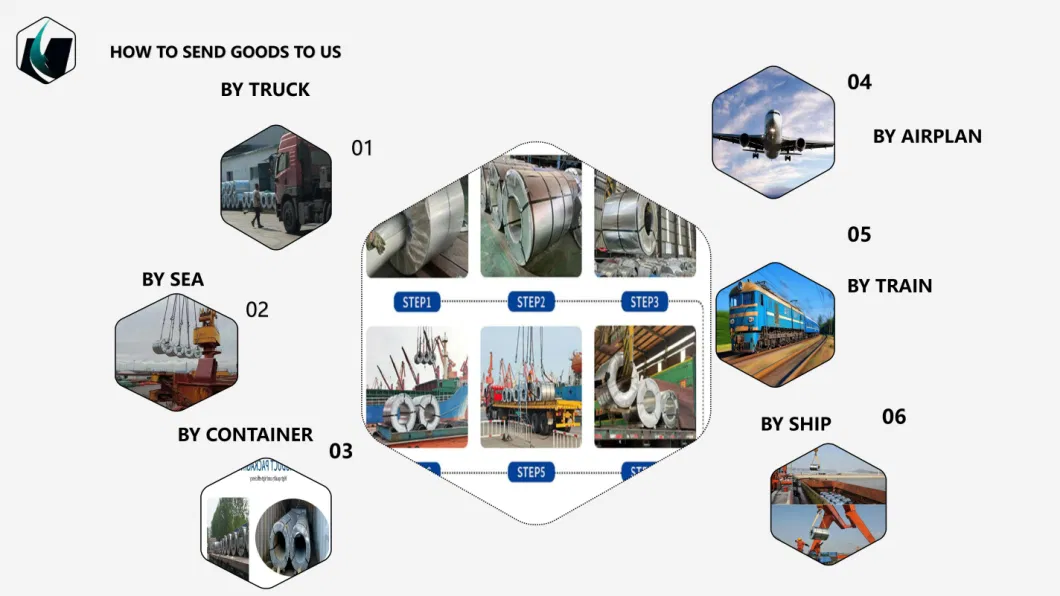

Loading & delivery

Three layers of packing, inside layer is kraft paper, middle layer is water plastic film, outside layer is steel strips.load by wooden pallet.

Our Services

1. Prompt reply for inquiry within 24 hours

2. One on one service guarantees you the best purchasing experience.

3. Strong production capacity and professional technical engineer can gusrantee the delivery time and quality.

4. Strict quality control

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness,coating and the quantity you need topurchase.

Q:What are the shipping ports?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can choose other ports according to your requirements.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:How long does your delivery time take?

A:ln general, our delivery time is within 7-15 days, and may be delayed if the demand is extremely large or specia circumstances occur.

Q:Canl go to your factory to visit?

A:0f course, we welcome customers from all over the world to visit our factory. However, some of the plants are not open to the public.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested forquality before packaging, and ungualified products wilbe destroyed.

Q:How to pack the products?

A:Theinner layer has a waterproof paper outerlaverwithironpackagingandis fixedwitha fumigation wooden pallet. lt careffectively protect products from corrosion during ocean transportation.