Basic Info.

Model NO.

LK-TGM-007

Surface

Smooth

Application

Hydraulic Project, Geotechnical Project, Environmental Project

Feature

Puncture Resistance, Impact Resistance, Tear Resistance

Material

PP\Pet

Color

White

Width

1m-8m (as Customrized)

Length

50m, 100m or Customized

Packing

Woven Plastic Bag

Standard

ASTM GM13

Delivery Time

Within 15day

Transport Package

Woven Bag

Specification

high-density polyethylene

Trademark

Looking-forward

Origin

Shandong, China

HS Code

5602100000

Production Capacity

20000sqm/Day

Packaging & Delivery

Package Size

500.00cm * 40.00cm * 40.00cm

Package Gross Weight

119.000kg

Product Description

China PET Polyester Filament Nonwoven Geotextile Manufacturer

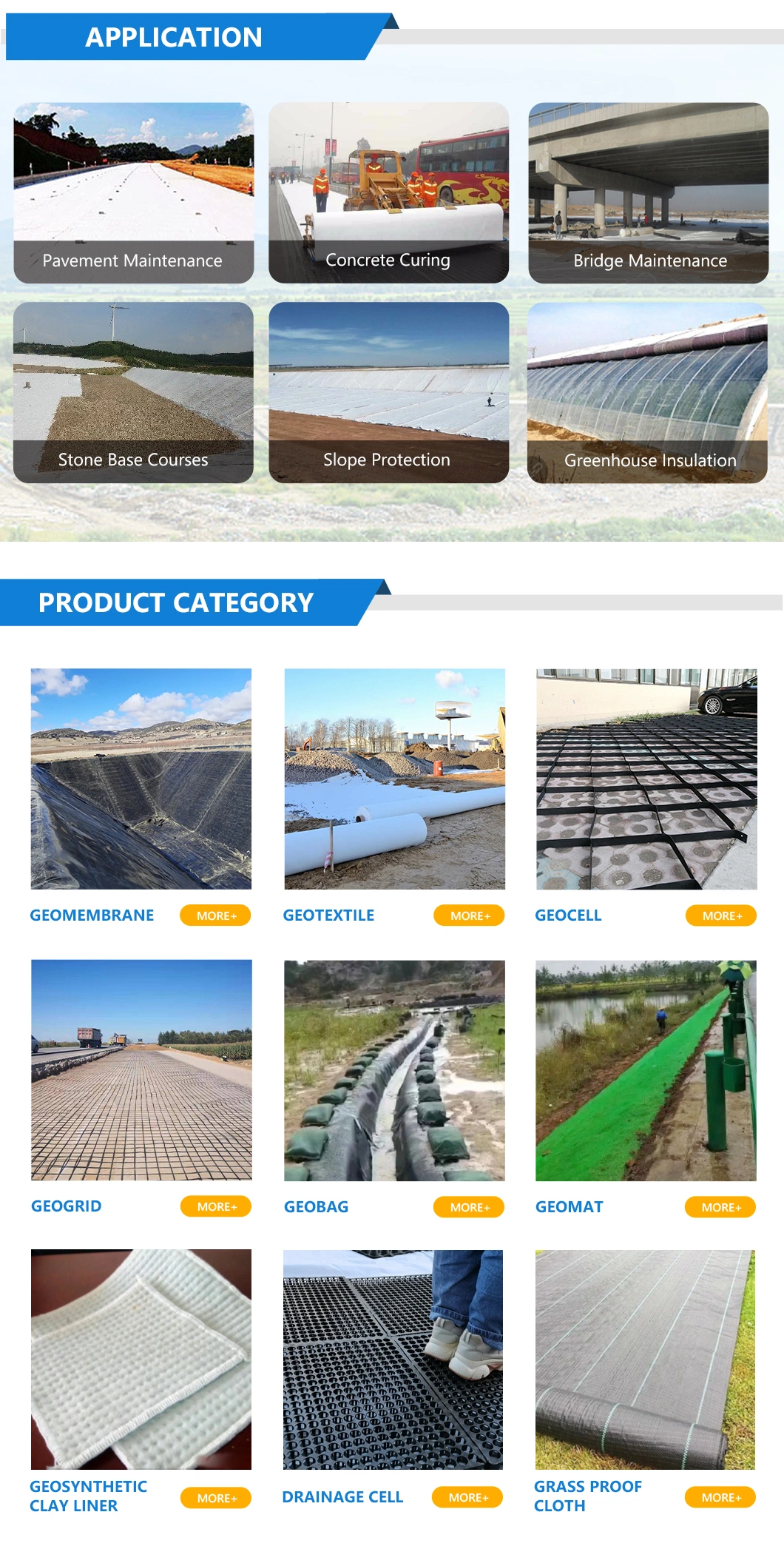

Application:

Application:

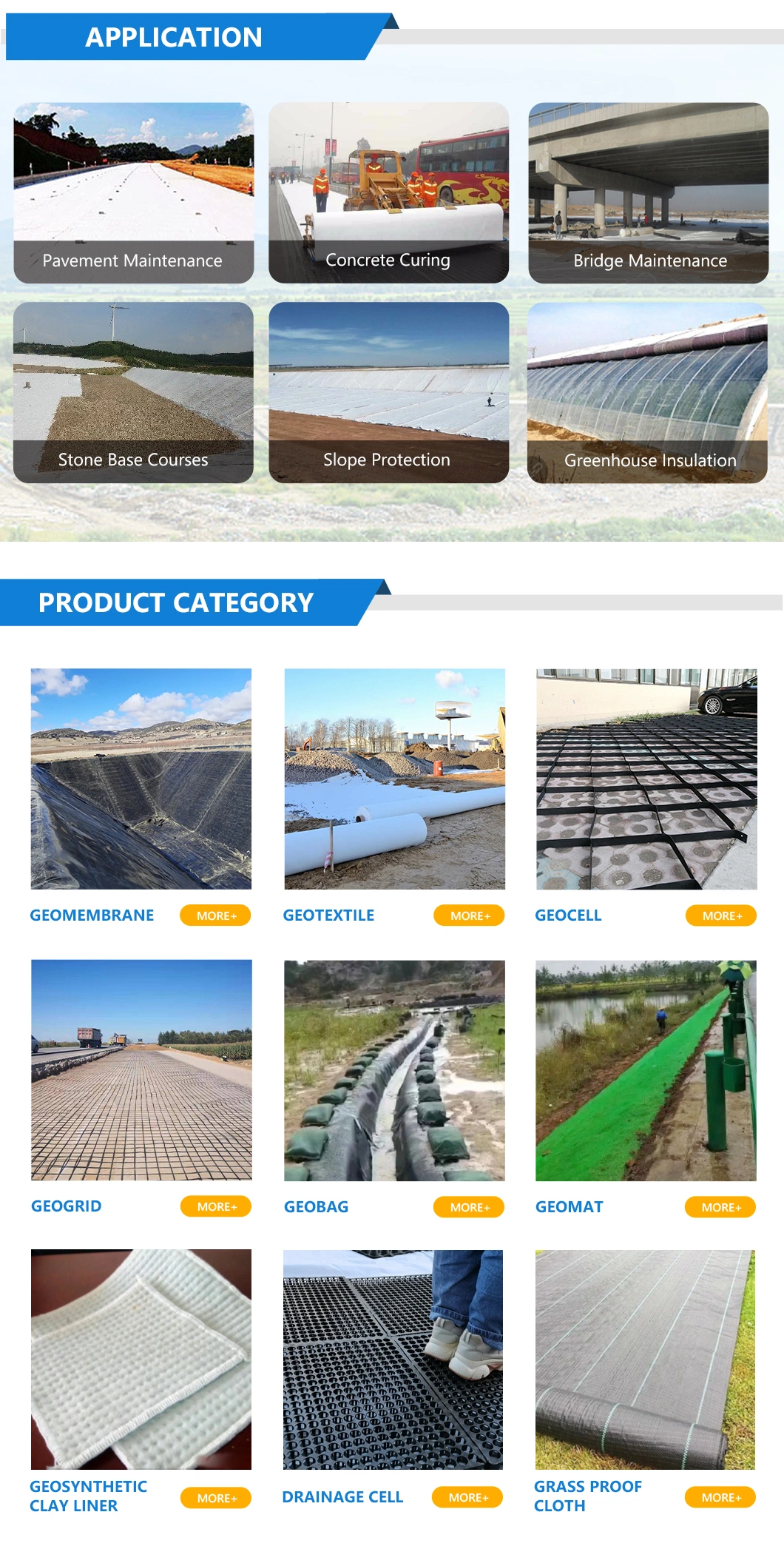

1. Reinforcement effect: Used in rock engineering such as highways, railways, airports, stone dams, slope embankments, retaining walls, and embankments, to disperse soil stress, increase soil modulus, limit soil slip, and improve stability.

2. Protection function: prevent the embankment from being washed away by wind, waves, tides, and rain, and use it for bank protection, slope protection, bottom protection, and soil erosion prevention.

3. Reverse filtration: Used as a filter layer for embankments, dams, rivers, and coastal rocks, soil slopes, and retaining walls, to prevent sand particles from passing through and allow water or air to pass freely.

TDS technical indicators

Application:

Application:1. Reinforcement effect: Used in rock engineering such as highways, railways, airports, stone dams, slope embankments, retaining walls, and embankments, to disperse soil stress, increase soil modulus, limit soil slip, and improve stability.

2. Protection function: prevent the embankment from being washed away by wind, waves, tides, and rain, and use it for bank protection, slope protection, bottom protection, and soil erosion prevention.

3. Reverse filtration: Used as a filter layer for embankments, dams, rivers, and coastal rocks, soil slopes, and retaining walls, to prevent sand particles from passing through and allow water or air to pass freely.

TDS technical indicators

| Specification | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remark |

| Quality deviation per unit acreage% | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | |

| Thickness, mm≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 | |

| Width deviation for range, %m | -0.5 | |||||||||||

| Mightiness at break, KN/m ≥ | 4.5 | 7.5 | 10.0 | 12.5 | 15.0 | 17.5 | 20.5 | 22.5 | 25.0 | 30.0 | 40.0 | Vertical and horizontal |

| Elongation at break, % | 40-80 | |||||||||||

| CBR bursting strength, KN≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 | |

| Effective aperture O90 (O95) mm | 0.07-0.20 | |||||||||||

| Vertical osmotic coefficient, cm/s | K x(10-1-10-3) | K=1.0-9.9 | ||||||||||

| Tearing strength, KN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 | Vertical and horizontal |