Basic Info.

Model NO.

custom

Width

90mm-1600mm

Weight Range

10-100GSM

Application

Dust Proof Respirator; Surgical Respirator

Grade

Domestic

Size

Customized

Life

Long

Product Feature

Fine, Breathable

Advantage

High Quality. Customized

Transport Package

Roll Package

Specification

customized

Trademark

Hedai

Origin

China

HS Code

5603129000

Production Capacity

1000 Tons / Year

Product Description

PRODUCT DESCRIPTION

This melt blown filter fabric is the key part of respirators which can provide majority of the protection. It can be widely used in disposable respirator, re-used dust respirators and surgical respirators. Our PP melt-blown nonwoven fabric can meet different standard requirement, including NA NOish N serial, EU standard EN 149 FFP serials and BFE serials.

EU FFP Serials (EN 149:2001)

Test Method: TSI 8130 @ 0.33 um, 60L/Min, DOP

Marks: This FFP serial product can reach to 99.8% filtration rate with the air resistance less 160Pa. The parameter is obviously better than European standard requirement, 99% filtration rate and 300Pa resistance. Same performance is shown in the standard of FFP1 and FFP2.

US N Serials (NIOSH 42 CFR-84 & GB 2626-2006)

Test Method: TSI 8130 @ 0.33 um, 60L/Min, DOP

Marks: This N99 product can reach to 99.5% filtration rate with the air resistance less 95Pa. The parameter is obviously better than N99 standard requirement, 99% filtration rate and 120Pa resistance. Same performance is shown in the standard of N90, N99 and N100 products.

Medical/Personal care face mask BFE series

Test Method: TSI 8130 @ 0.33 um, 60L/Min, DOP

Marks: Basically, under the melt-blown processing nonwovens has larger resistance while the filtration efficiency is higher with the case of same weight per square meter.

PRODUCT SHOWS

PRODUCT ADVANTAGES

Static Electret Charging Fabric

We own serials of static electret charging technology, including customized formula with electret master batch, patented high voltage charging equipment with special designed charging panel. Thanks to the adoption of electret our PP melt-blown nonwovens can reach higher filtration efficiency under the case of not changing air flow resistance property. So the other performance parameter of filtration efficiency, penetration pressure, air resistance, ageing resistance can obviously get higher score than other like products.

Proudct Features

1. Structure with fine or ultra-fine fibre, bigger total surface area

2. High filtration efficiency and low resistance

3. Can filter harmful particles as well as bacteria in the air

4. More stable filtration efficiency and longer service life

5. High porosity and small pore size

6. Good chemical stability and wide temperature usage

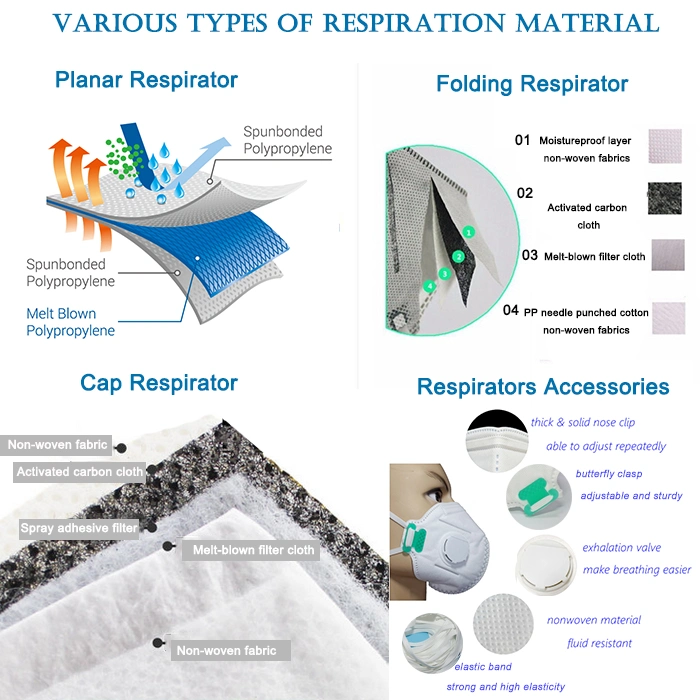

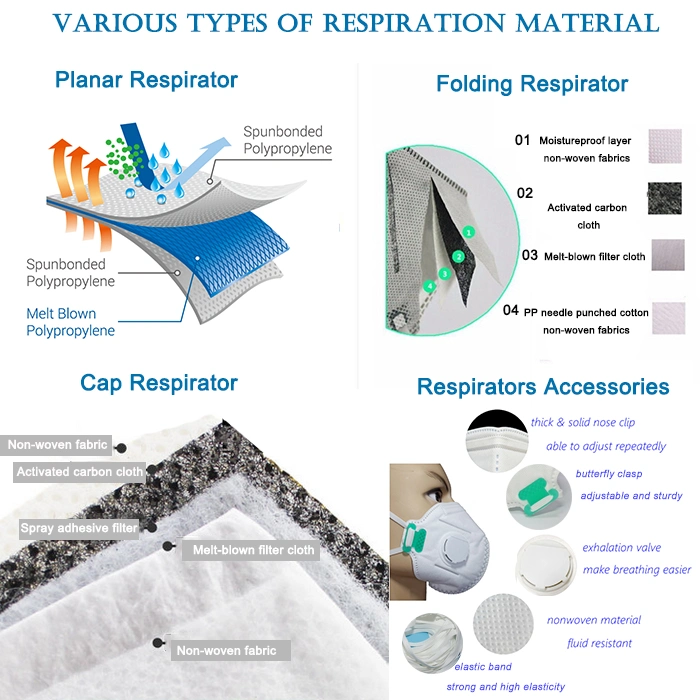

Various Types Of Respiration Material

We can supply the various types of nonwoven fabric for the production of mask. We can also supply other accesaries needed for respirators production.

ABOUT OUR MELT-BLOWN NONWOVEN

PP Melt-blown nonwoven is the most popular material as the high efficiency filter media in the application of air filtration, mainly used in the production of personal care products like masks and respirators; industrial air cleaning products like HEPA filter bags, as well as the medical instrument like masks used in hospital. At the same time, PP melt-blown nonwovens can be laminated with other kinds of nonwoven products to fit for wide range of air cleaning products like ventilation filters, cabin air filters, vacuum cleaner filters and other household air cleaning filters.

OTHER TYPES OF NONWOVEN FABRIC

We supply the various of types of nonwoven fabric used as the filter media in the field of air and liquid filtration. Our product categories include PP melt-blown nonwovens, PP spun-bonded nonwovens, PET fibre hot-rolling nonwovens, PET fibre spun-bonded nonwovens, PET filament thermos-bonded nonwovens, Needle punched nonwovens, Activated cabbon filter media, Ultrasonic composite nonwovens, etc.

PRODUCT SERVICES

1. We provide laboratory test result for each roll products for quality tracking.

2. We offer other accesories needed for respirators production

3. Test equipment for Meltblown filters

4. Technical solutions for filter production

5. We can customize filter media specification to reduce the material loss

6. We can arrange to ship the goods by various means of transportation, via air, sea, truck, rail or combined

COMPANY INFORMATION

We produce melt-blown nonwovens which is mainly used as filter media in the production of respirators. We are specialized in melt-blown technology and have more than 12 years of experience in melt-blown nonwovens production. We developed our own electret charging equipment and electret master batch, adopting unique formula, to help with our nonwovens reach higher filtration efficiency and lower air penetration pressure.

This melt blown filter fabric is the key part of respirators which can provide majority of the protection. It can be widely used in disposable respirator, re-used dust respirators and surgical respirators. Our PP melt-blown nonwoven fabric can meet different standard requirement, including NA NOish N serial, EU standard EN 149 FFP serials and BFE serials.

EU FFP Serials (EN 149:2001)

| Standard | Basisi weight (gsm) | Resistance (Pa) | Filtration efficiency (%) | MAIN USAGE |

| FFP 1 | 40 | 70 | >93% | FFP 1 standard respirator, 3-ply flat mask. 3-ply flat mask |

| 80 | 50 | >93% | bulky and soft product, lower air resistance, higher dust capacity | |

| FFP 2 | 45 | 125 | >99% | lower basis weight of FFP 2 standard respirator filter media, economical and practical product |

| 60 | 110 | >99% | FFP 2 standard respirator, fit for mine, severe air condition workshops etc | |

| 100 | 90 | >99% | lower air resistance and higher dust capacity for high standard respirator | |

| FFP 3 | 90 | 150 | >99.5% | FFP 3 standard respirator, high filtration environment requirement eg. chemical lab |

Test Method: TSI 8130 @ 0.33 um, 60L/Min, DOP

Marks: This FFP serial product can reach to 99.8% filtration rate with the air resistance less 160Pa. The parameter is obviously better than European standard requirement, 99% filtration rate and 300Pa resistance. Same performance is shown in the standard of FFP1 and FFP2.

US N Serials (NIOSH 42 CFR-84 & GB 2626-2006)

| Standard | GSM | Resistance (Pa) | Filtration efficiency (%) | MAIN USAGE |

| N 90 | 30 | < 60 | >93% | Economic product, lower cost |

| 60 | < 40 | >95% | bulky and soft product, lower air resistance, higher dust capacity Can replace 3M 9001 products | |

| N 95 | 30 | < 90 | >98% | lower basis weight of N 95 standard respirator filter media, economical and practical product |

| 50 | < 60 | >98% | N 95 standard respirator, fit for mine, severe air condition workshops etc | |

| 80 | < 50 | >98% | Bulky and soft product, lower air resistance, higher dust capacity | |

| N 99 | 80 | < 95 | >99.5% | N99 standard respirator, cup shape mask. |

| N 100 | 120 | < 145 | >99.995% | N100 standard respirator, very high filtration efficiency |

Marks: This N99 product can reach to 99.5% filtration rate with the air resistance less 95Pa. The parameter is obviously better than N99 standard requirement, 99% filtration rate and 120Pa resistance. Same performance is shown in the standard of N90, N99 and N100 products.

Medical/Personal care face mask BFE series

| Standard | Basis weight (gsm) | Resistance (Pa) | Bacterial Filtration efficiency (%) | Particle Filtration Efficiency (%) | MAIN USAGE |

| BFE 99 | 22 | 25 | >99.5% | Medical care Mask | |

| BFE 99 | 25 | 30 | >99% | Personal care Mask |

Test Method: TSI 8130 @ 0.33 um, 60L/Min, DOP

Marks: Basically, under the melt-blown processing nonwovens has larger resistance while the filtration efficiency is higher with the case of same weight per square meter.

PRODUCT SHOWS

If you have any questions, please feel free to contact with us.

PRODUCT ADVANTAGES

Static Electret Charging Fabric

We own serials of static electret charging technology, including customized formula with electret master batch, patented high voltage charging equipment with special designed charging panel. Thanks to the adoption of electret our PP melt-blown nonwovens can reach higher filtration efficiency under the case of not changing air flow resistance property. So the other performance parameter of filtration efficiency, penetration pressure, air resistance, ageing resistance can obviously get higher score than other like products.

Proudct Features

1. Structure with fine or ultra-fine fibre, bigger total surface area

2. High filtration efficiency and low resistance

3. Can filter harmful particles as well as bacteria in the air

4. More stable filtration efficiency and longer service life

5. High porosity and small pore size

6. Good chemical stability and wide temperature usage

Various Types Of Respiration Material

We can supply the various types of nonwoven fabric for the production of mask. We can also supply other accesaries needed for respirators production.

ABOUT OUR MELT-BLOWN NONWOVEN

PP Melt-blown nonwoven is the most popular material as the high efficiency filter media in the application of air filtration, mainly used in the production of personal care products like masks and respirators; industrial air cleaning products like HEPA filter bags, as well as the medical instrument like masks used in hospital. At the same time, PP melt-blown nonwovens can be laminated with other kinds of nonwoven products to fit for wide range of air cleaning products like ventilation filters, cabin air filters, vacuum cleaner filters and other household air cleaning filters.

OTHER TYPES OF NONWOVEN FABRIC

We supply the various of types of nonwoven fabric used as the filter media in the field of air and liquid filtration. Our product categories include PP melt-blown nonwovens, PP spun-bonded nonwovens, PET fibre hot-rolling nonwovens, PET fibre spun-bonded nonwovens, PET filament thermos-bonded nonwovens, Needle punched nonwovens, Activated cabbon filter media, Ultrasonic composite nonwovens, etc.

PRODUCT SERVICES

1. We provide laboratory test result for each roll products for quality tracking.

2. We offer other accesories needed for respirators production

3. Test equipment for Meltblown filters

4. Technical solutions for filter production

5. We can customize filter media specification to reduce the material loss

6. We can arrange to ship the goods by various means of transportation, via air, sea, truck, rail or combined

COMPANY INFORMATION

We produce melt-blown nonwovens which is mainly used as filter media in the production of respirators. We are specialized in melt-blown technology and have more than 12 years of experience in melt-blown nonwovens production. We developed our own electret charging equipment and electret master batch, adopting unique formula, to help with our nonwovens reach higher filtration efficiency and lower air penetration pressure.

If you have any questions, please feel free to contact with us.