Basic Info.

Packaging & Delivery

Product Description

| Steel-Plastic Composite Geogrid: (ISO/CE Certificates) | ||||||||

| Specification | 30-30 | 40-40 | 50-50 | 60-60 | 80-80 | 100-100 | 150-150 | |

| Tensile Strength (KN/M) | Warp | 30 | 40 | 50 | 60 | 80 | 100 | 150 |

| Weft | 30 | 40 | 50 | 60 | 80 | 100 | 150 | |

| Elongation % | ≤ 3 | |||||||

| Drawing Force at 2% Elongation Ratio (KN/M)≥ | 27 | 32 | 45 | 54 | 67 | 84 | 127 | |

| Width (m) | 6±0.06 | |||||||

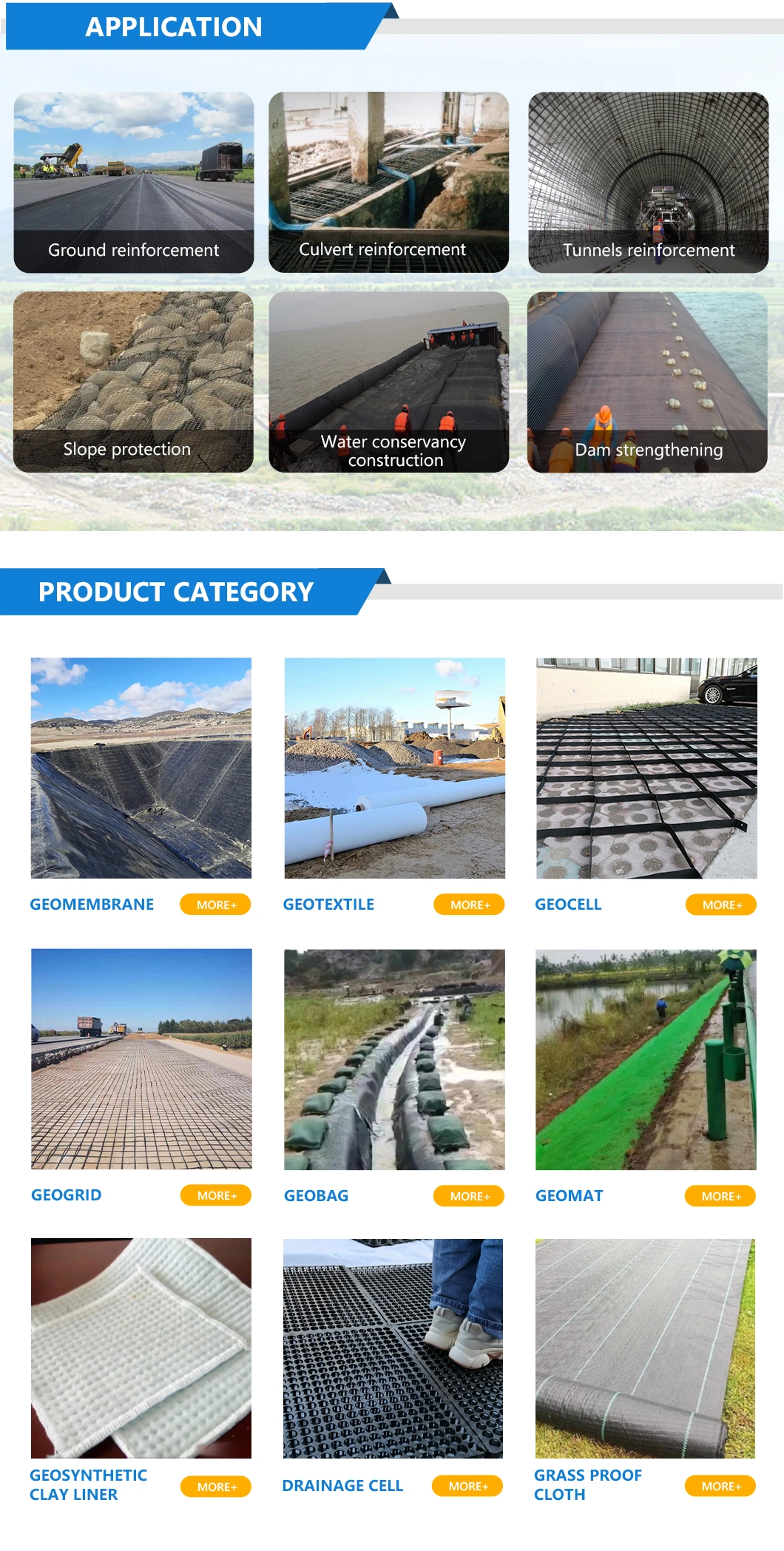

Application:

Application:1. Suitable for enhancing the roadbed and pavement of various highways, railways, and airports.

2. Suitable for permanent bearing foundation reinforcement in large parking lots and dock freight yards.

3. Suitable for slope protection of railways and highways.

4. Applicable culvert reinforcement.

5. Suitable for secondary reinforcement of soil slopes after unidirectional tensile geogrid reinforcement, further enhancing the soil slope and preventing soil erosion. Reinforcement of mines and tunnels

1.Product description:

The steel plastic two-way geogrid is made of high-strength steel wire (or other fibers), specially treated, polyethylene (PE) or polypropylene (PP), and added with other additives. By extrusion, it becomes a composite high-strength tensile strip with rough embossing on the surface, which is a high-strength reinforced geogrid. This single strip is formed by using a fusion welding technique with special reinforcement bonding to weld its junction points, and is woven or sandwiched at a certain distance in the longitudinal and transverse directions. It is a reinforced geogrid.

2.Main Features

1. With high strength, low creep, and adaptability to various environmental soils, it can fully meet the use of tall retaining walls in high-grade highways.

2. It can effectively improve the interlocking and interlocking effects of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrict the lateral displacement of the soil, and enhance the stability of the foundation.

3. Compared with traditional grids, they are more characterized by high strength, strong bearing capacity, corrosion resistance, aging resistance, large friction coefficient, uniform perforation, convenient construction, and long service life.

4. It is more suitable for deep-sea operations and embankment reinforcement, fundamentally solving the technical problems of low strength, poor corrosion resistance, and short service life caused by long-term seawater erosion of gabions made of other materials.

5. It can effectively avoid construction damage caused by rolling and damage by machines and tools during the construction process.

3.Application scenario:

It can be used for civil engineering projects such as highway, railway, embankment, abutment, construction access, wharf, revetment, flood embankment, dam, mudflat treatment, freight yard, slag yard, airport, sports ground, environmental protection buildings, soft soil foundation reinforcement, retaining wall, slope protection and pavement resistance.

4.Construction specification:

When applying geogrids to soft foundation treatment, the design strength of geogrids should be determined based on the height of subgrade fill, while determining the location and number of layers of geogrids based on geological conditions.

When the filling height is greater than 4m, it is sufficient for the geogrid to meet the minimum requirements of industry standards, and the longitudinal and lateral ultimate tensile force should not be less than 20kN/m

When the filling height is between 3-4 m, the ultimate tensile force of the geogrid in both vertical and horizontal directions shall not be less than 40 kN/m

When the filling height is less than 3m, the vertical and horizontal ultimate tensile force of the geogrid is not less than 50 kN/m, and the elongation is less than 4%. It is recommended to use GSZ60-60 geogrid. When the geogrid is used for the filling and excavation joint of the subgrade, a two-way geogrid of not less than 40 kN/m should be used, and GSZ60-60 geogrid should be used

When used to widen the junction of old and new roads, the method of using grids for the expansion of Shenyang-Dalian Expressway should be used for reference. For subgrade with a filling height of more than 3 meters, a steel plastic composite grid should be paved at a distance of 20 cm from the top of the subgrade. Steel plastic composite grids with a longitudinal (vertical route direction) ultimate tensile force greater than or equal to 60 kN/m and a transverse (parallel route direction) ultimate tensile force greater than or equal to 20 kN/m should be used, with an elongation of ≤ 4%.

The geomembrane roll are in the hand sewing woven bag packing, safe and scratch-proof.

The bag color can be customized, with your own logo