Basic Info.

Product Description

- Product Introduction

| terial | Customization of HDPE, EVA, PVC, PE, etc | Color | Black Blue, etc |

| Thickness | 0.5-2.0/mm customized | Width | 1m-8m |

| Length | 100m, 50m or Customized | Package | Woven Bag |

| Certificate | SGS SHI | Test Method | ASTM D |

| Type | Smooth & Textured | Transport Package | Woven Bag |

| Specification | Customized | Trademark | INNO |

| Origin | China | HS Code | 3920109090 |

| Production Capacity | 300000 Square Meters Per Day | ||

SPECIFICATIONS:

UV Protected

Tough and long lasting

- Technical Data:

| Item | Unit | Standard | 0.5mm | 0.75mm | 1.0mm | 1.5mm | 2.0mm | |

| Density | G/CM3 | D1505 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |

| Tensile Yield Strength | Kn/m | D6693 | 9 | 11 | 15 | 22 | 29 | |

| Tensile break Strength | kn/m | D6693 | 15 | 20 | 27 | 40 | 53 | |

| Tensile Break Elongation | % | D6693 | 700 | 700 | 700 | 700 | 700 | |

| Tear Resistance | N | D1004 | 60 | 93 | 125 | 187 | 249 | |

| Puncture Resistance | N | D4833 | 120 | 240 | 320 | 480 | 640 | |

| Stress Crack Resistance | hr | D5397 | 500 | 500 | 500 | 500 | 500 | |

| Dimensional Stability | % | ±2 | ||||||

| Oven Aging at 85ºCafter 90 days Standard OIT -% High Pressure OIT-% | % | D5721 D3895 D5885 | 55 80 | |||||

| Oxidative Induction time Standard OIT High Pressure OIT | min | D3895 D4885 | 100 400 | |||||

| UV Resistance High Pressure OIT -% Retained After 1600 hrs | % | D5885 | 50 | |||||

Packing details:

| Packing details | Width | Length | Containers type |

| Black bags for outer package | 5.8m | follow your request | 20GP |

| 7m | 40'GP/40'HC | ||

| 8m | 40'GP or 40'HC |

INNO COMPANY ONLY PRODUCE 100% VIRGIN MATERIAL

1.Waterproof and impermeable

2.UV resistance

2.High tearing resistance

3.Puncture-resisting

4.Nontoxic

5.Long life,20years exposed to sun, buriend 60years

6.Root resistance

- Municipal environmental projects , water conservancy projects

- Landfill cap(closures), mining heap leach pads

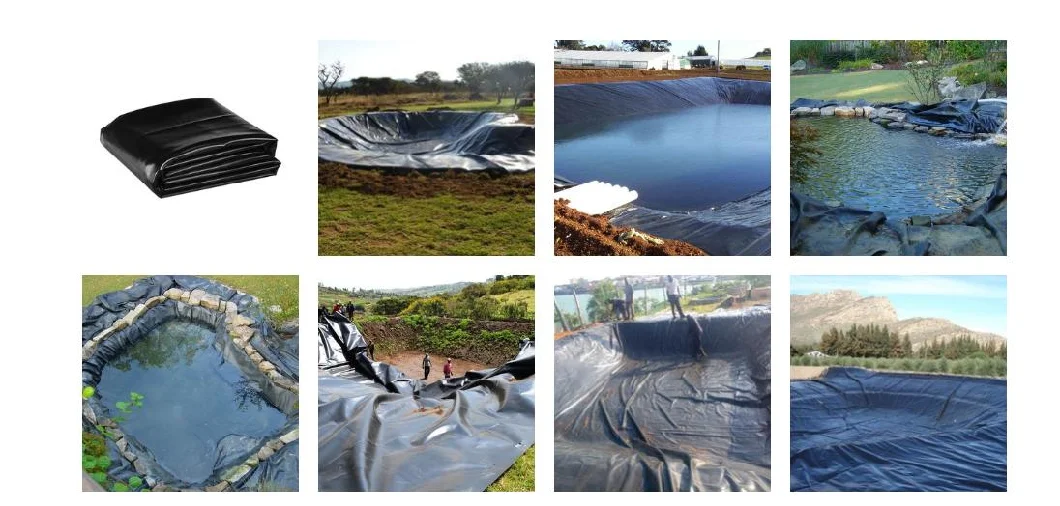

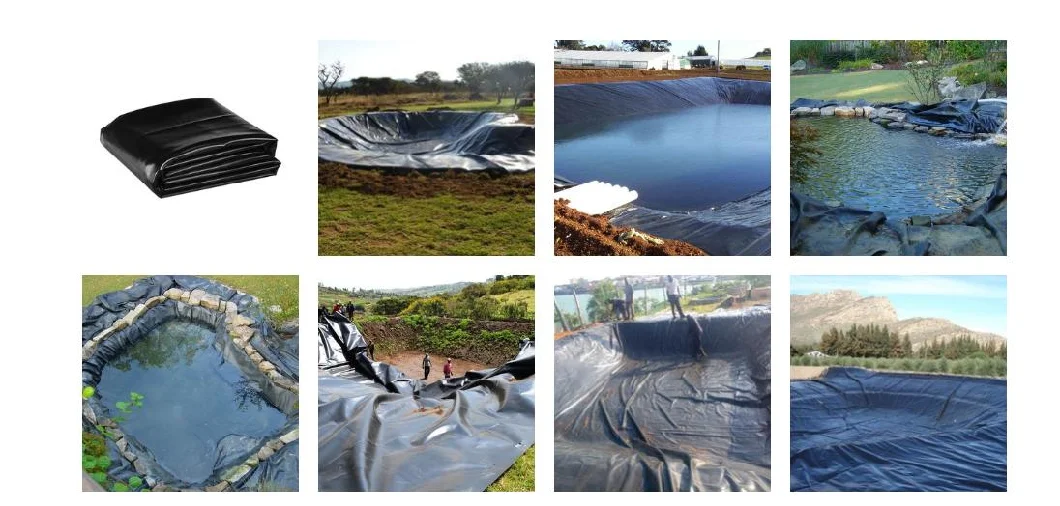

- Pond liner, canal linings, tank linings, raw water treatment reservoirs, retention ponds,

- Waste water treatment lagoon, secondary containment

- solid waste landfills, Hazardous waste landfills

INNO geomembrane adopted the first class automatic production equipment and three-layer pressing technology. All geomembrane quality is meeting with GB, GRI and ASTM test standard.

HDPE Geomembrane Application:

1.Environmental protection, environmental hygiene (such as garbage landfill site, treatment of sewage, containment of poisonous or harmful wastes, hazardous warehouse, industry wastes, construction & explosive rubbish, etc)

2. Water conservancy (such as waterproofing, stopping up leak, reinforcement for lake, river, channels, tunnels, dams and reservoirs; vertical wall with core, slope protection, etc)

3. Municipal engineering (expressway, subway, underground engineering of building; and liner of roof pool, roof garden's waterproofing, sewage channel, etc)

4. Garden (backing & slope protection of artificial lake, pool, golf course's pond)

5. Petrochemicals (liner secondary lining of chemical reeaction tank and deposit tank from chemical plant & refinery; seepage control of oil tank from gas station)

6. Mining (backing seepage of washing pond, heap leaching pond, ashery, dissolved pond, deposit pond from the stack and tailing)

7. Traffic facilities (highway foundation reinforcement, culvert stopping up leak)

8. Agriculture (stolling up leak for reservoirs, drinking pools, storage ponds and irrigation system)

9. Aquaculture industry (seepage control for sea cucumber circle's slope protection, liner of fish pool & shrimp pond)

10. Seepage, corrosion, leaks control & reinforcement for other facility, leachate collection

11.Temporary container structure, prefabrication of special parts

Packaging & Shipping

Installation

Upon request by the customer, Dajin can also offer a full turnkey installation service, covering the materials manufactured by Inno , any other geosynthetics products, installation and all additional materials required to fully complete the project.

We have supervisors and installers, with or without welding equipment, such as machines and tools, to manage a group of local staff supplied by the customer.

We can also provide training courses to staff provided by the customer.

Good quality and good services:

(1)Service:

A. OEM/ODM orders are warmly welcome

B. All of our products have proceeded testing before shipment and we guaranteed the good quality.

(2) Quality Control:

We have established a national-standard laboratory for in-house quality control and built a strict quality control system in all aspects from raw materials testing and production processes to final product quality testing.

Not only is stringent internal quality control carried out at INNO, but regular testing and analyzing of our product performance is implemented by authoritative testing organizations in Europe and the United States.

Q1: Are you a factory or trading company? Where is your company located?

A1: We are a manufacturer/factory. Our company is located in Shandong, China.

Q4:How to get the sample?

we only charge the freight fee. The freight fee will be returned If you place the order.