Basic Info.

Model NO.

innovat-1.2.3

Application

Retaining Wall

Viscose

Without Viscose

Function

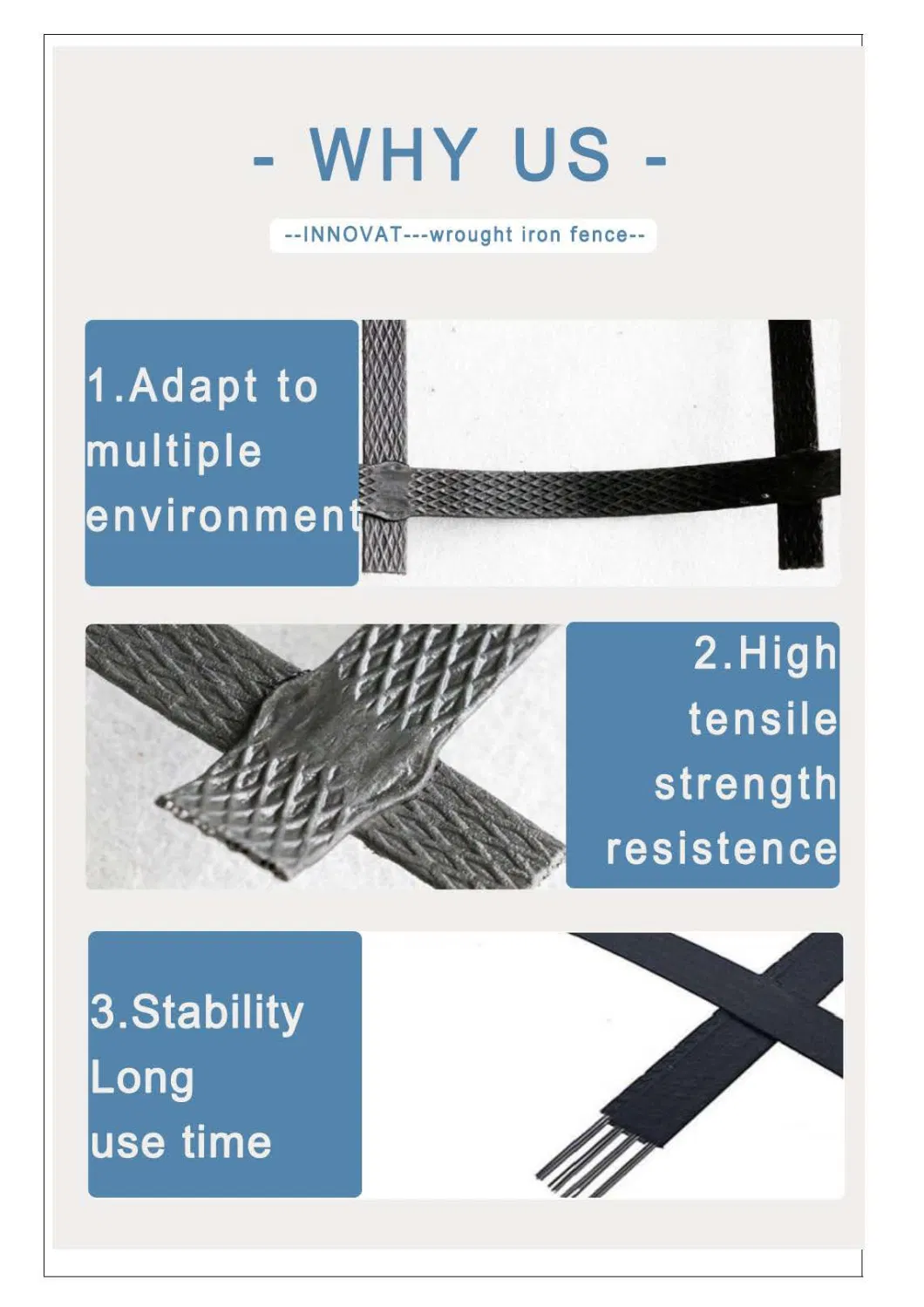

Anti-Slip, Reinforcement

Classification

Polyester Geogrid

Material

Polyester

After-Sales Service

Available

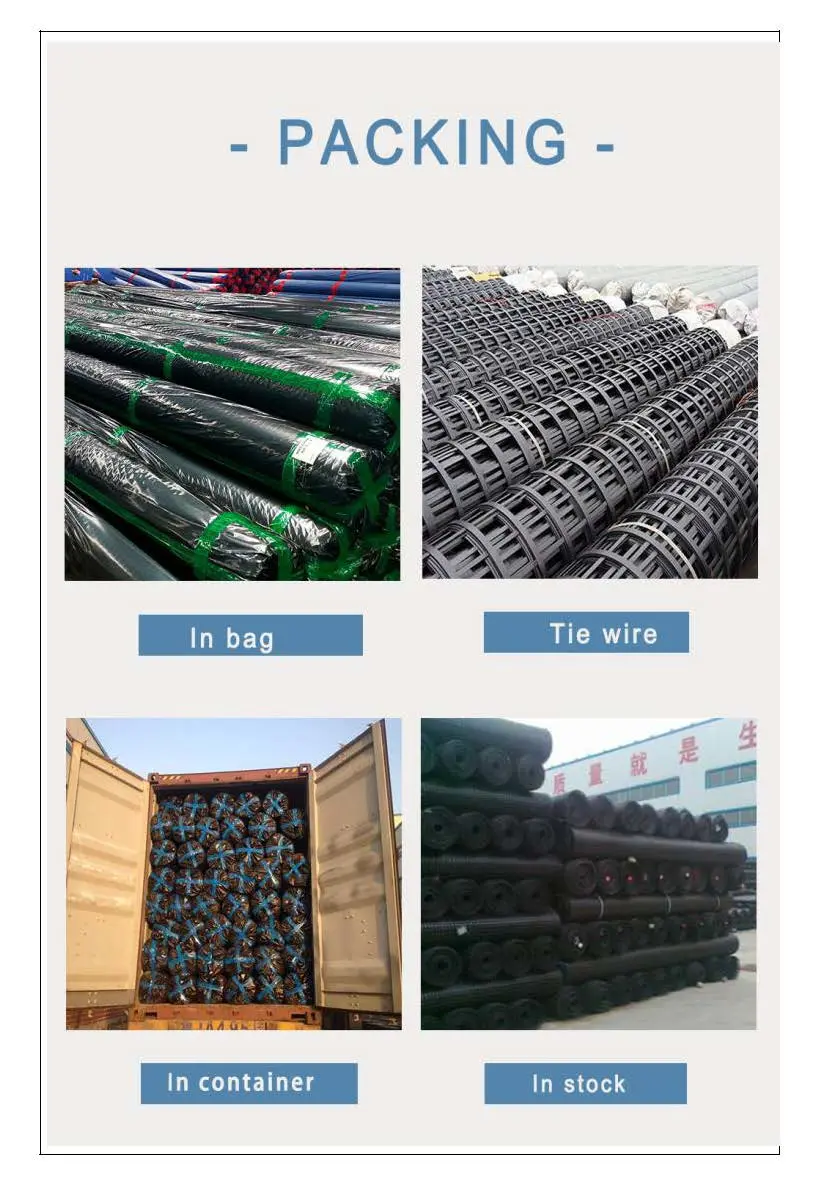

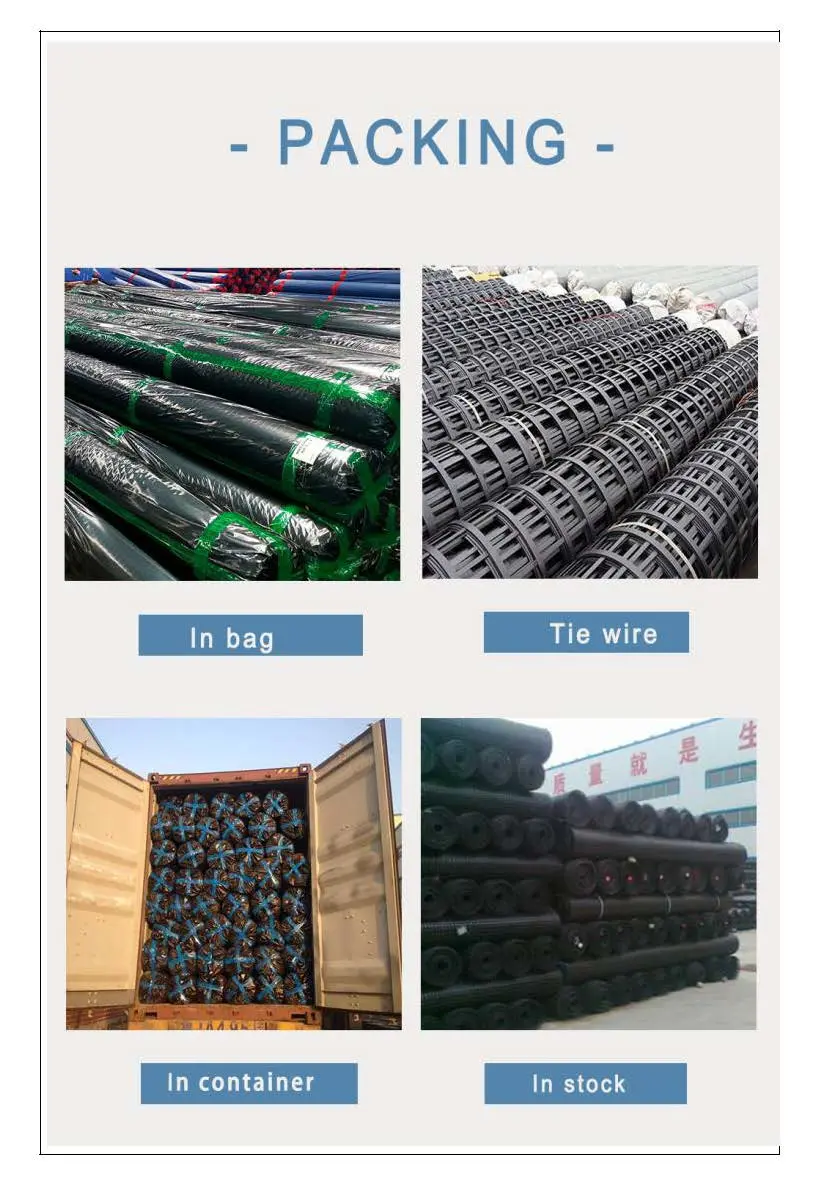

Transport Package

Pallet

Specification

100cm*100cm*80cm

Trademark

INNOVAAT

Origin

China

HS Code

731441

Production Capacity

5000rolls/Month

Packaging & Delivery

Package Size

100.00cm * 90.00cm * 120.00cm

Package Gross Weight

200.000kg

Product Description

Steel plastic geogrid mesh is made from high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding and composite processing technology. Steel plastic geogrid is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement. Due to reinforced steel biaxial geogrid combined with the regular rough pattern on the surface, the steel plastic geogrid mesh has great tensile strength, perfect corrosion resistance and excellent wear and tear resistance, etc. The stress and the friction between the soil and the fill generally limit the shearing of the foundation and the lateral extrusion bulge. The high rigidity of the reinforced soil cushion by the steel plastic geogrid mesh is beneficial to the diffusion of the upper foundation load and the uniform distribution. To the lower soft soil layer, the bearing capacity of the foundation is better improved. Due to the effect of the reinforced mat soil layer, the overall rigidity of the foundation within the compression layer is increased, which is beneficial to adjust the deformation of the foundation. Steel plastic geogrid reinforcement can effectively enhances the bearing capacity of foundation and prevents the soil from lateral displacement due to its high friction coefficient and the bearing capacity. The reinforced soil composite cushion formed with the help of the reinforced steel plastic geogrid mesh can even absorb the earthquake energy well, so its seismic performance is good.

Ease of Construction: he Geogrid can be installed in any weather conditions. This makes it more demanding.

Land Optimization: This method of Geogrid installation in soils makes an unsuitable area suitable for preparing it to meet desired properties for construction. Geogrid thus helps in proper land utilization.

Geogrid promotes soil stabilization

A higher strength soil mass is obtained

Higher load bearing capacity

It is a good remedy to retain soil from erosion

No requirement of mortar. The material is implemented dry.

No difficulty in material availability

Geogrids are flexible in nature. They are known for their versatility.

Geogrids have high durability reducing maintenance cost. They are highly resistant against environmental influences.

Materials are tested based on standard codes and regulations.

Butt together at edges - DO NOT overlap geogrid.

Eliminate any folds or looseness in the Geogrid by pulling tight and staking at the back.

Always backfill and compact one course of block at a time.

Keep an adequate cushion of soil between the geogrid and equipment

Guardrail beams we supply are 10 gauge and 12 gauge materials,which process is going through flattening, punching, galvanizing or plastic coating,fabricating and shearing process.

We supply and manufacture beam guardrails in accordance with China National Standard JT/T281-1995(Corrugated Sheet Steel Beams For Expressway Guardrail - China), AASHTO M-180(Corrugated Sheet Steel Beams For Highway Guardrail - USA), RAL-RG620 (German) or

any other International Standards. The base steel we use meets Steel Grade Q235B (equivalent to S235JR according to DIN EN 10025 and

Gr. D according to ASTM A283M) or Q345 (S355JR / ASTM A529M 1994).

The company has advanced guardrail plate forming machine, which can realize the strip head removal, smoothing, punching, cutting, forming, leveling and other working procedure, so that the guardrail has good consistency, high processingaccuracy,low production cost, which is widely recognized by the market.

The company has an advanced production line of plastic spraying and hot-dip galvanizing for guardrail . According to the different

construction environment, corresponding surface treatment can be adopted to achieve good corrosion resistance, moisture

resistance and weather resistance.

| Product name | Steel Plastic Geogrid Mesh | |||||||

| Item | GSZ30 | GSZ40 | GSZ50 | GSZ60 | GSZ80 | GSZ100 | GSZ150 | |

| Tensile Strength (kN/m) | Longitudinal | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

| Transverse | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 | |

| Elongation Rate (%) | Longitudinal | ≤2 | ||||||

| Transverse | ≤2 | |||||||

| Strength at 1% elongation (KN/m) | Longitudinal | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

| Transverse | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 | |

| Limit peel force at welded bonded point N | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | |

| Features |

Land Optimization: This method of Geogrid installation in soils makes an unsuitable area suitable for preparing it to meet desired properties for construction. Geogrid thus helps in proper land utilization.

Geogrid promotes soil stabilization

A higher strength soil mass is obtained

Higher load bearing capacity

It is a good remedy to retain soil from erosion

No requirement of mortar. The material is implemented dry.

No difficulty in material availability

Geogrids are flexible in nature. They are known for their versatility.

Geogrids have high durability reducing maintenance cost. They are highly resistant against environmental influences.

Materials are tested based on standard codes and regulations.

| Installation Tips |

Eliminate any folds or looseness in the Geogrid by pulling tight and staking at the back.

Always backfill and compact one course of block at a time.

Keep an adequate cushion of soil between the geogrid and equipment

Guardrail beams we supply are 10 gauge and 12 gauge materials,which process is going through flattening, punching, galvanizing or plastic coating,fabricating and shearing process.

We supply and manufacture beam guardrails in accordance with China National Standard JT/T281-1995(Corrugated Sheet Steel Beams For Expressway Guardrail - China), AASHTO M-180(Corrugated Sheet Steel Beams For Highway Guardrail - USA), RAL-RG620 (German) or

any other International Standards. The base steel we use meets Steel Grade Q235B (equivalent to S235JR according to DIN EN 10025 and

Gr. D according to ASTM A283M) or Q345 (S355JR / ASTM A529M 1994).

The company has advanced guardrail plate forming machine, which can realize the strip head removal, smoothing, punching, cutting, forming, leveling and other working procedure, so that the guardrail has good consistency, high processingaccuracy,low production cost, which is widely recognized by the market.

The company has an advanced production line of plastic spraying and hot-dip galvanizing for guardrail . According to the different

construction environment, corresponding surface treatment can be adopted to achieve good corrosion resistance, moisture

resistance and weather resistance.